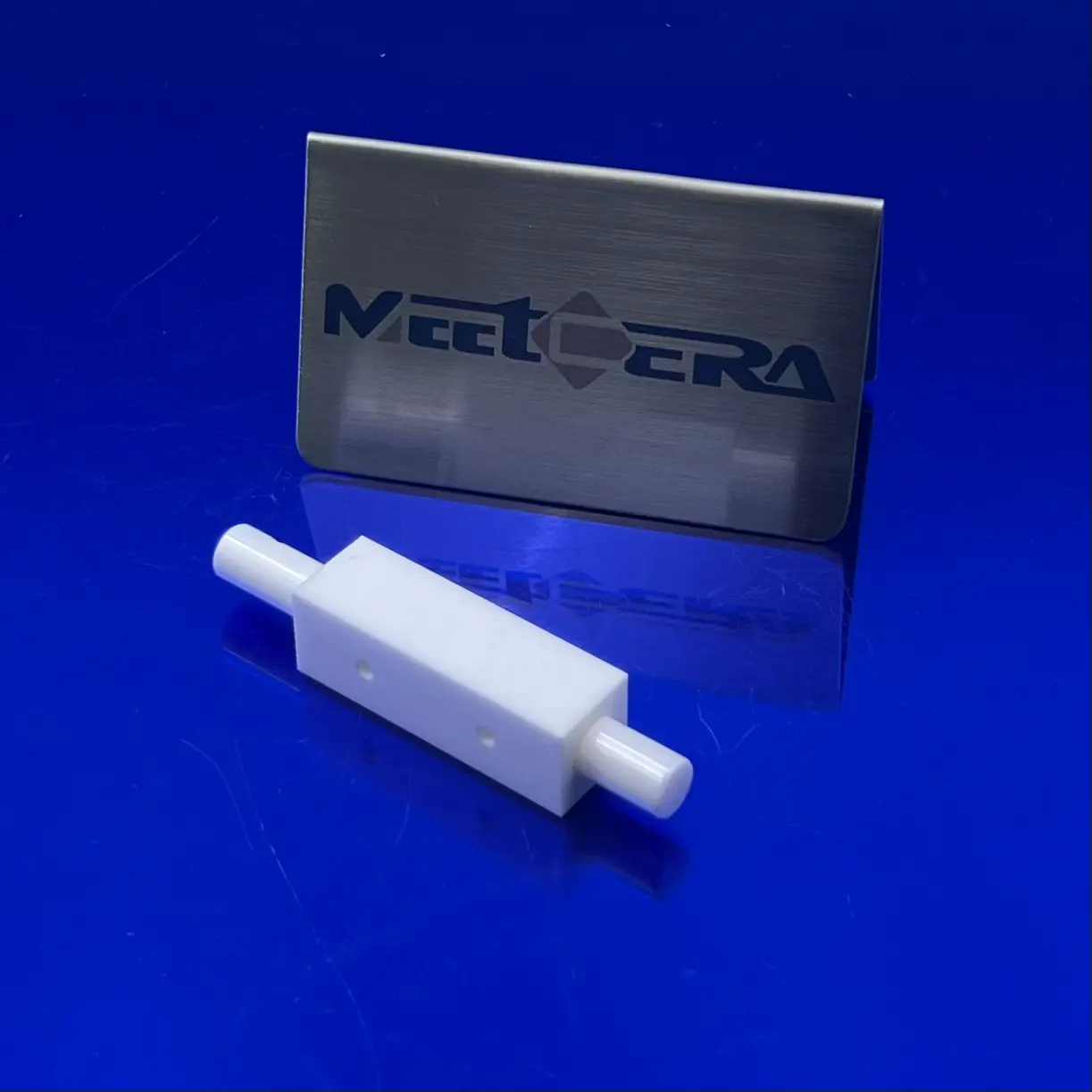

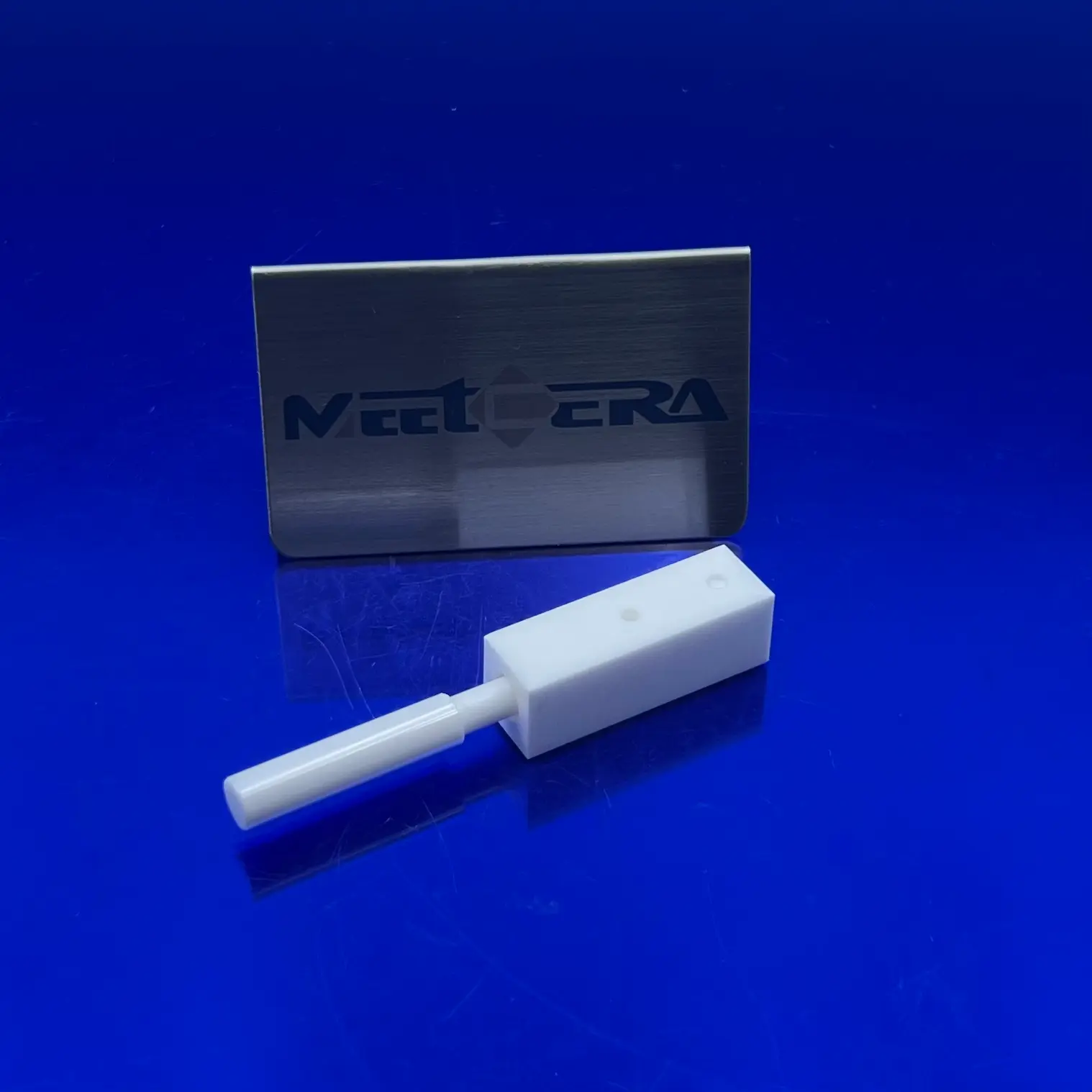

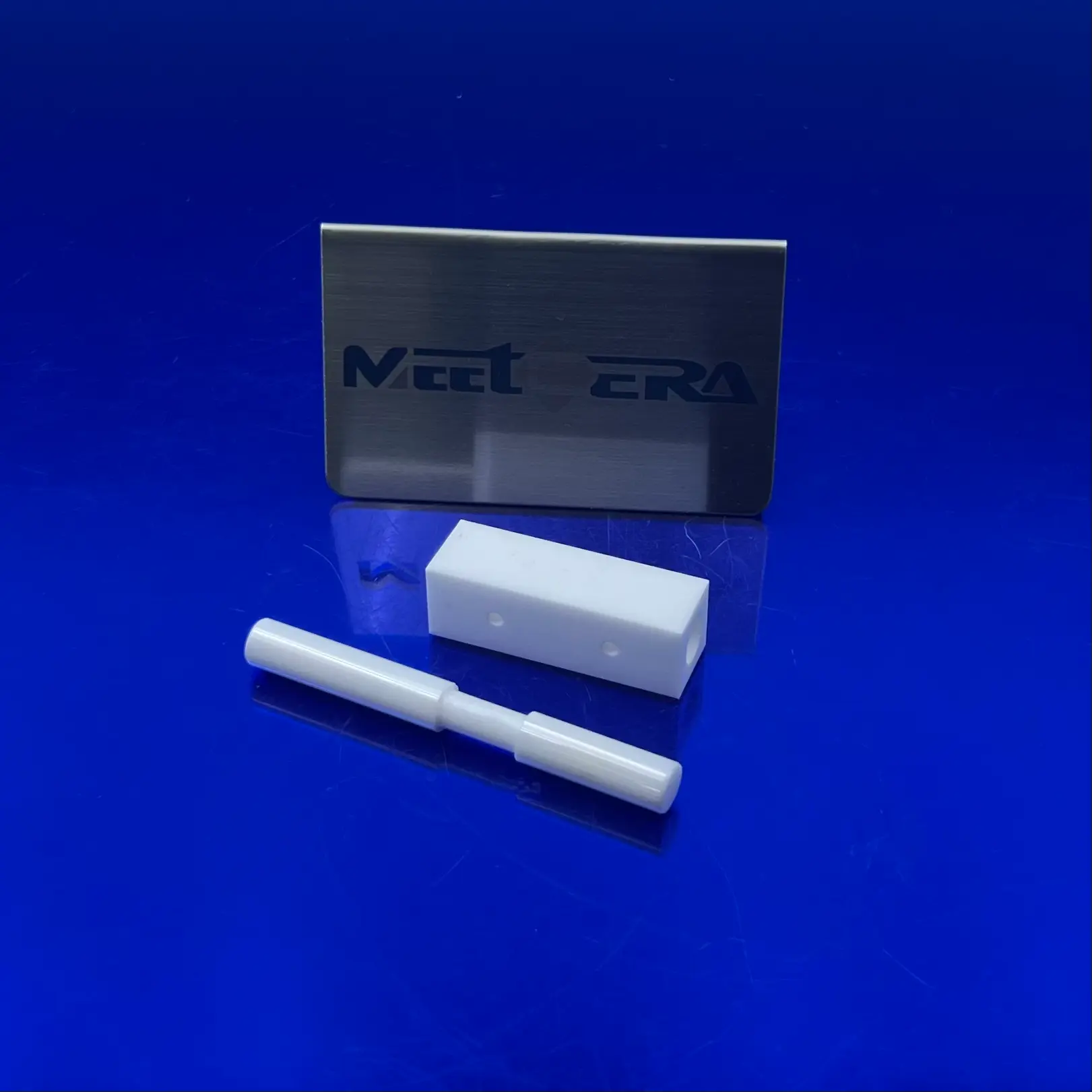

Zirconia Ceramic Plunger with Bushing

The Zirconia Ceramic Plunger with Bushing is a high-performance precision component engineered for demanding industrial applications. Crafted from premium zirconia (ZrO2) ceramic material, this plunger combines exceptional durability, corrosion resistance, and smooth operation with an integrated bushing for enhanced stability and reduced friction. Ideal for use in pumps, valves, and fluid handling systems, it ensures reliable performance in harsh environments where traditional metal components may fail.

Key Features:

- Material Excellence: Made from high-purity zirconia ceramic, known for its superior hardness (Mohs scale 8.5+), thermal stability (up to 2,400°C), and chemical inertness. The bushing is seamlessly integrated to provide precise alignment and wear protection.

- Precision Engineering: Tight tolerances (±0.001 mm) for optimal fit and function, ensuring minimal leakage and maximum efficiency in high-pressure systems.

- Corrosion and Wear Resistance: Outperforms stainless steel or plastic alternatives by resisting acids, alkalis, and abrasive media, extending service life up to 10 times longer.

- Low Friction Design: The bushing reduces operational friction, minimizing energy consumption and heat generation during use.

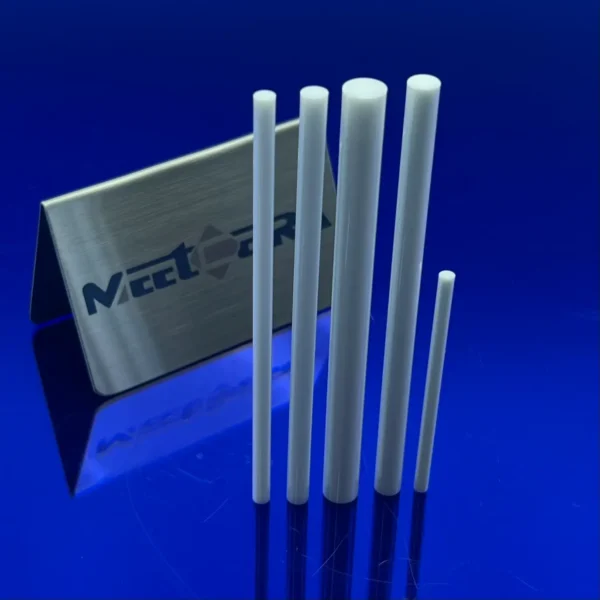

- Customization Options: Available in various sizes (diameter: 5-50 mm, length: 50-300 mm) and configurations to meet specific OEM requirements.

Benefits:

- Enhanced Durability: Withstands extreme pressures (up to 500 MPa) and temperatures, reducing downtime and maintenance costs.

- Improved Efficiency: Smooth surface finish (Ra < 0.2 μm) promotes fluid flow without turbulence, ideal for metering and dosing applications.

- Biocompatibility and Safety: Non-toxic and hypoallergenic, making it suitable for medical, food processing, and pharmaceutical industries.

- Cost-Effective Longevity: Lower total ownership costs due to reduced replacement frequency and compatibility with aggressive chemicals.

Applications:

- Industrial Pumps: High-pressure plunger pumps for chemical processing, oil & gas, and water treatment.

- Medical Devices: Precision syringes and infusion pumps requiring sterile, wear-resistant components.

- Automotive and Aerospace: Fuel injection systems and hydraulic actuators.

- Food & Beverage: Handling viscous fluids without contamination.

- Laboratory Equipment: Analytical instruments and chromatography systems.

Frequently Asked Questions (FAQ)

1.What are the main advantages of zirconia ceramic over metal plungers?

Zirconia offers superior corrosion resistance, higher hardness, and longer lifespan in harsh environments, reducing maintenance needs.

2.Can this plunger handle high temperatures?

Yes, it operates reliably from -200°C to +1,200°C, making it ideal for extreme thermal conditions.

3.Do you offer custom sizes or configurations?

Absolutely, we provide customization for diameters, lengths, and coatings to fit your specific application requirements.