Why Are Ceramics Good Insulators?

The question "Why are ceramics good insulators?" delves into the fundamental material properties that make ceramics1 highly effective at preventing the flow of electrical current. This is a crucial understanding for engineers and designers working with electrical systems, as the selection of appropriate insulating materials is paramount for safety and performance. The core of the answer lies in the unique atomic structure and bonding characteristics inherent in most ceramic materials.

Can Poor Insulation Lead to Electrical Hazards?

Insufficient electrical insulation2 can result in dangerous situations where electrical current flows through unintended paths, potentially causing electric shocks to personnel or igniting flammable materials. This poses a severe safety risk in homes, workplaces, and industrial settings. Doesn’t the failure of insulating materials directly endanger human lives and property due to the risk of electrocution and fire?

Indeed, the use of inadequate insulators creates a significant safety hazard, leading to potential electrical shocks, burns, and even fatalities, alongside the risk of fire and property damage.

| Insulation Material | Typical Resistivity (Ω·m) | Risk of Electrical Hazard (Low Resistivity) |

|---|---|---|

| Copper | 1.7 x 10⁻⁸ | High (Conductor) |

| Aluminum | 2.8 x 10⁻⁸ | High (Conductor) |

| Semiconductors | 10⁻⁵ – 10¹⁰ | Moderate to High (Variable) |

| Polymers | 10¹⁰ – 10¹⁶ | Low to Moderate |

| Ceramics | 10¹² – 10¹⁸ | Very Low |

Will Ineffective Insulation Cause Energy Loss?

When insulating materials fail to properly contain electrical current, leakage currents can occur. These unwanted currents dissipate energy as heat, leading to inefficiencies in electrical devices and power transmission systems. Doesn’t the use of poor insulators contribute to significant energy wastage and increased operational costs?

Absolutely, ineffective insulation allows for current leakage, resulting in energy loss in the form of heat, which lowers the efficiency of electrical systems and increases energy consumption and associated expenses.

| Insulation Material | Typical Dielectric Loss Tangent (at 1 MHz) | Impact on Energy Loss (High Loss Tangent) |

|---|---|---|

| Some Polymers | 0.001 – 0.01 | Moderate |

| Glass | 0.0001 – 0.001 | Low to Moderate |

| Porcelain | 0.0005 – 0.005 | Low to Moderate |

| Alumina Ceramics | 0.0001 – 0.0005 | Very Low |

Can Degradation of Insulation Lead to Equipment Failure?

Over time, insulating materials can degrade due to factors such as heat, moisture, chemical exposure, and electrical stress. This degradation can compromise their insulating properties, leading to premature equipment failure and costly downtime. Doesn’t the use of materials with poor long-term stability as insulators increase the likelihood of equipment malfunction and the need for frequent replacements?

Indeed, insulators that degrade easily under operational stress lead to a higher incidence of equipment failure, resulting in production interruptions, repair costs, and a reduced lifespan of electrical assets.

| Degradation Factor | Common Insulating Materials Affected | Consequence of Degradation |

|---|---|---|

| Heat | Polymers, some ceramics | Reduced dielectric strength, embrittlement |

| Moisture | Polymers, porous ceramics | Surface tracking, reduced resistivity |

| Chemical Exposure | Polymers, some glasses | Corrosion, structural weakening |

| Electrical Stress | All insulators | Dielectric breakdown, aging |

Will Bulky Insulation Limit Device Miniaturization?

In many modern electronic devices, there is a strong trend towards miniaturization. Insulating materials with low dielectric strength or high dielectric constant may require larger volumes to provide adequate insulation, hindering the development of smaller and more compact devices. Doesn’t the need for bulky insulation limit the progress in miniaturizing electronic equipment and achieving higher component density?

Absolutely, if insulating materials require significant volume to function effectively, they impede the miniaturization of electronic devices, making it challenging to create smaller, lighter, and more portable technologies.

| Insulation Material | Typical Dielectric Constant (at 1 MHz) | Impact on Miniaturization (High Constant) |

|---|---|---|

| Air | 1 | Minimal |

| Some Polymers | 2 – 10 | Moderate |

| Some Ceramics | 5 – 1000+ | High (Variable) |

| Alumina Ceramics | 9 – 10 | Moderate |

Doesn’t the wide energy band gap3 in ceramics effectively prevent electrons from participating in electrical conduction?

In solid materials, electrons occupy specific energy bands. For a material to conduct electricity, electrons must be able to move to a higher energy band (the conduction band) where they are free to move. Ceramics typically have a large energy band gap between the filled valence band and the empty conduction band. This large gap requires a significant amount of energy to excite electrons into the conduction band, which is not readily available under normal operating conditions.

Absolutely, the large energy band gap in ceramics acts as a significant barrier, preventing electrons from gaining enough energy to jump into the conduction band and contribute to electrical current flow under typical voltage and temperature conditions.

| Material Type | Typical Energy Band Gap (eV) | Ability to Conduct Electricity |

|---|---|---|

| Conductors | 0 | High |

| Semiconductors | 0.1 – 3 | Moderate (tunable) |

| Insulators | > 3 | Very Low |

| Ceramics | 3 – 9 | Very Low |

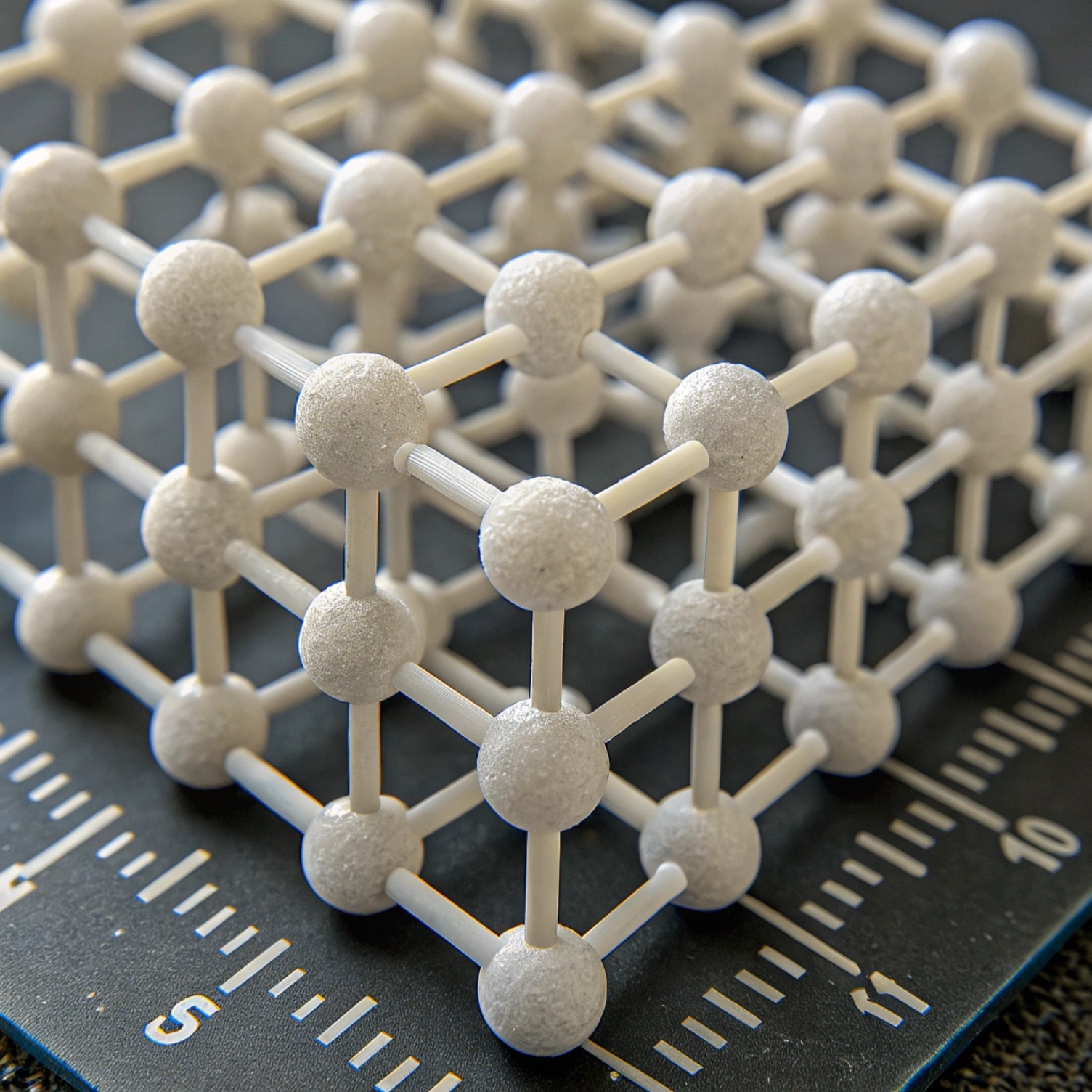

Doesn’t the ordered atomic arrangement in ceramics contribute to their insulating properties by reducing the disruption of potential charge carrier movement?

Many ceramics possess a highly ordered crystalline structure. This regular arrangement of atoms minimizes the scattering of any stray electrons that might become mobile due to thermal excitation. Reduced scattering means that even if a few electrons do enter the conduction band, their movement is still significantly impeded.

Indeed, the well-defined crystal lattice of many ceramics minimizes imperfections and atomic vibrations that could scatter moving electrons, further hindering electrical conductivity.

| Material Structure | Impact on Electron Scattering | Effect on Conductivity | Example Materials |

|---|---|---|---|

| Ordered Crystalline | Minimal | Low (Insulators) | Alumina, Silicon Dioxide |

| Polycrystalline | Moderate | Moderate to Low | Many technical ceramics |

| Amorphous | High | Low to Moderate | Some glasses, polymers |

The increasing demand for smaller and lighter devices across various industries necessitates innovative approaches to electrical insulation. While traditional methods often involve bulky components, advanced ceramic engineering offers viable pathways to achieve both lightweight and miniaturization without compromising the crucial insulation performance required for safety and reliability.

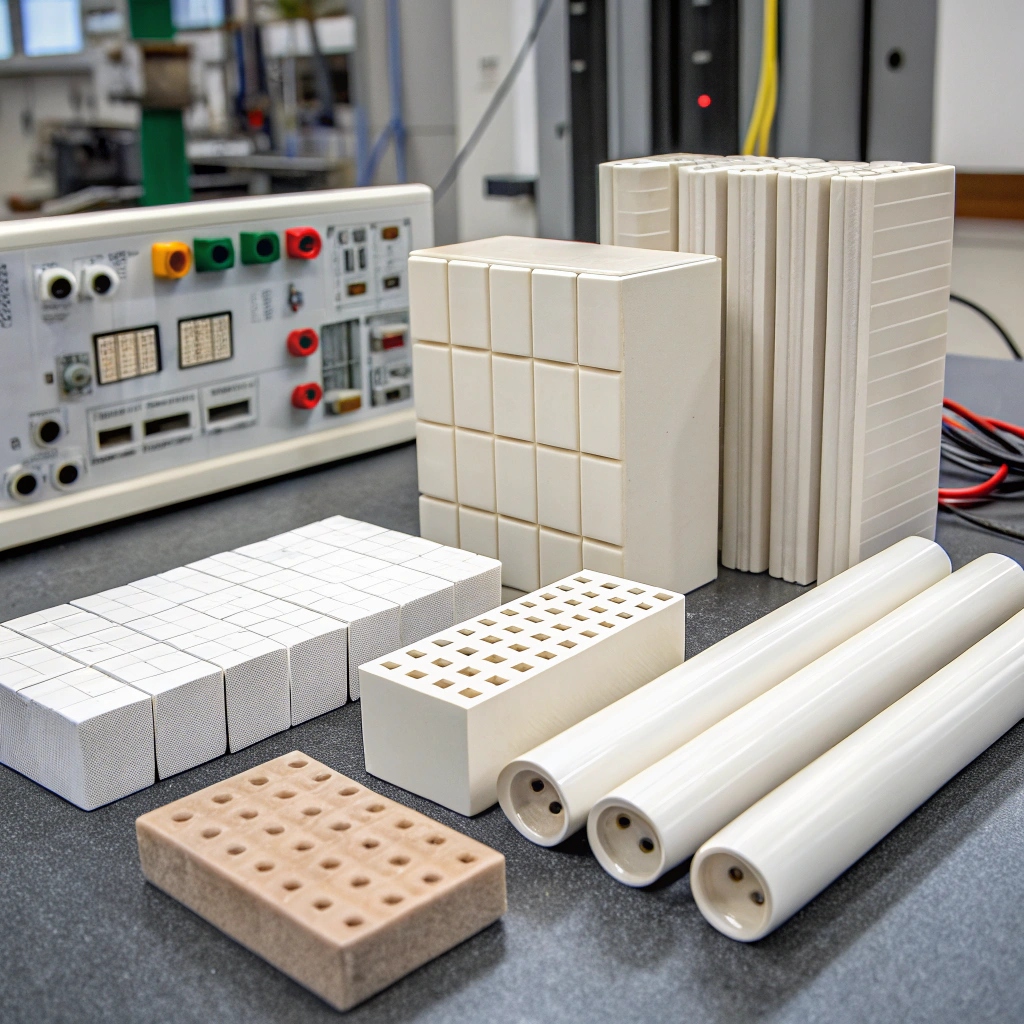

Achieving Lightweight and Miniaturization of Ceramic Materials While Ensuring Insulation Performance?

The question "How to achieve lightweight and miniaturization of ceramic materials4 while ensuring insulation performance?" highlights a critical challenge in modern engineering design, particularly in electronics, aerospace, and portable devices. The need for smaller, lighter components without compromising their ability to electrically insulate is paramount. This requires a delicate balance, as reducing size and weight can often lead to a decrease in insulation capability if not approached strategically.

Will Bulky Insulators Hinder Device Miniaturization?

In many applications, particularly portable electronics and aerospace, size and weight are critical factors. Using bulky ceramic insulators5 to ensure sufficient insulation performance directly impedes the miniaturization of devices and systems, limiting their portability and integration capabilities. Doesn’t the necessity for large insulators restrict the design of smaller, more efficient electronic devices and aerospace components?

Indeed, the reliance on bulky insulation materials directly hinders the trend towards miniaturization, leading to larger, heavier devices with limited portability and integration flexibility.

| Device/System | Insulation Requirement (High Voltage) | Impact of Bulky Insulators |

|---|---|---|

| Portable Electronics | High energy density, compact size | Larger device footprint, increased weight |

| Aerospace Systems | Lightweight, high reliability | Increased system weight, reduced payload capacity |

| Medical Implants | Small size, biocompatibility | Larger implant size, patient discomfort |

Can Increased Weight Reduce Efficiency and Performance?

In applications where weight is a significant concern, such as aerospace and electric vehicles, the use of heavier ceramic insulators to compensate for lower intrinsic insulation properties adds to the overall weight of the system. This increased weight can negatively impact fuel efficiency, maneuverability, and overall performance. Doesn’t the added weight from oversized insulators compromise the efficiency and performance of weight-sensitive systems?

Absolutely, the extra weight contributed by bulky insulators reduces the efficiency of transportation systems and the performance of portable devices, leading to increased energy consumption and limited operational capabilities.

| Application | Weight Sensitivity | Impact of Increased Insulator Weight |

|---|---|---|

| Electric Vehicles | High | Reduced range, lower acceleration |

| Drones | High | Shorter flight time, reduced payload |

| Wearable Electronics | High | User discomfort, limited battery life |

Will Compromised Insulation Lead to Safety Concerns?

If miniaturization is achieved at the expense of adequate insulation performance, it can lead to electrical breakdown, leakage currents, and potential safety hazards, especially in high-voltage applications. This trade-off between size and safety is a critical concern for both manufacturers and end-users. Doesn’t the pursuit of miniaturization without ensuring sufficient insulation integrity create significant safety risks for high-voltage devices?

Indeed, compromising insulation performance for the sake of miniaturization can lead to dangerous electrical failures, posing severe safety risks to users and the environment.

| Scenario | Potential Insulation Failure | Safety Hazard |

|---|---|---|

| High-Voltage Miniaturization | Dielectric breakdown | Electric shock, fire |

| Compact Power Supplies | Surface leakage | Short circuits, overheating |

| Small Medical Devices | Insulation degradation | Patient harm, device malfunction |

Can Manufacturing Complexity Increase Costs?

Achieving both lightweight and high insulation performance in miniaturized ceramics often requires advanced and complex manufacturing processes. These sophisticated techniques can lead to increased production costs, making the final products more expensive. Doesn’t the need for advanced manufacturing to achieve miniaturized, high-performance ceramic insulators drive up production costs?

Absolutely, the intricate processes required to produce lightweight and miniaturized ceramic insulators with superior insulation properties can significantly increase manufacturing complexity and, consequently, the overall cost of the final product.

| Manufacturing Process | Complexity Level | Impact on Cost |

|---|---|---|

| Thin-Film Deposition | High | High |

| Multi-Layer Ceramics | High | High |

| Advanced Sintering | Moderate to High | Moderate to High |

| Porous Ceramics | Moderate | Moderate |

The central issue is the requirement for materials that can reliably impede the movement of electrical charges. In electrical devices and power systems, uncontrolled current flow can lead to short circuits, overheating, and equipment failure, posing significant safety risks and operational disruptions. Therefore, materials with high electrical resistivity, known as insulators, are essential for directing current along desired paths and preventing unwanted leakage. Ceramics, with their intrinsic properties, excel in this role.

-

Explore how ceramics’ unique properties make them ideal for insulation in electrical applications, ensuring safety and efficiency. ↩

-

Learn about the dangers of inadequate electrical insulation and how it can lead to serious safety hazards and equipment failures. ↩

-

Discover the significance of the energy band gap in ceramics and its role in preventing electrical conduction, crucial for insulation. ↩

-

Explore innovative techniques and materials that enable the lightweight and miniaturization of ceramics without sacrificing performance. ↩

-

Learn about the challenges bulky insulators pose to miniaturization and how they affect device design and efficiency. ↩

No comment