X-ray Tube Parts and Functions: Complete Guide to Components

The X-ray tube is the core component in diagnostic imaging systems — from general radiography and fluoroscopy to CT scanners. It converts electrical energy into X-rays, with <1% becoming useful radiation and >99% turning into heat. Understanding x-ray tube components and their functions is essential for radiologic technologists, medical physicists, service engineers, and students to optimize image quality, ensure patient safety, and extend tube lifespan.

1.How an X-ray Tube Produces X-rays

X-ray production follows four key steps:

- Electron emission — A heated tungsten filament (cathode) releases electrons via thermionic emission.

- Electron acceleration — High voltage (kVp) pulls electrons toward the anode at high speed.

- X-ray generation — Electrons strike the anode target, producing X-rays mainly through Bremsstrahlung (continuous spectrum) and some characteristic radiation.

- Heat management & output — Most energy becomes heat; the useful X-ray beam exits through a low-attenuation window.

This process powers everything from chest X-rays to high-speed CT scans.

2.Major X-ray Tube Components and Their Functions

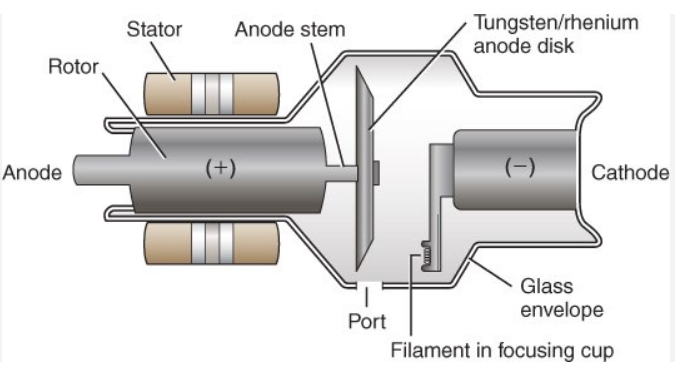

Modern diagnostic x-ray tubes (especially rotating anode designs used in 95%+ of hospital systems) include these essential parts:

(1). Cathode (Filament + Focusing Cup)

- Filament: Thin tungsten coil heated to ~2,400°C, emitting electrons (controls mA and tube current).

- Focusing cup: Shapes the electron beam into a tight focal spot (dual filaments common: small for high-resolution, large for high-output exams).

Key role: Determines focal spot size → directly affects image sharpness and spatial resolution.

Common issue: Filament evaporation and burnout — the #1 cause of tube failure (gradual thinning → eventual break).

(2). Anode (Target + Rotating Disc)

- Target: Tungsten or tungsten-rhenium disc (high melting point, Z=74 for efficient X-ray production).

- Rotating anode: Spins at 9,000–10,000 RPM to spread heat over a track instead of one spot.

Key role: Converts electron kinetic energy into X-rays while dissipating massive heat loads (allows higher mA and shorter exposures without pitting/melting).

Why rotating? Stationary anodes limit power; rotation increases heat capacity dramatically.

(3). Rotor & Stator Assembly

- Rotor: Inside the vacuum envelope, attached to the anode.

- Stator: External electromagnetic coils that drive rotation like an induction motor.

Key role: Enables smooth high-speed spinning essential for heat distribution.

(4). Tube Envelope

- Glass (older), metal-ceramic, or full metal construction.

- Maintains ultra-high vacuum (prevents electron scatter and arcing).

Key role: Allows free electron travel; modern metal envelopes resist tungsten vapor coating and extend life.

(5). Tube Housing & Cooling System

- Lead-lined metal casing surrounds the insert.

- Filled with insulating oil (circulates heat away); high-end units add water/air cooling.

Key role: Shields stray radiation, electrically insulates high voltage, and prevents overheating (includes expansion bellows for oil thermal changes).

Pro tip: Oil leaks or poor cooling → rapid failure (overheating alarms, arcing sounds).

3.Energy Conversion Summary

| Process Step | Input | Output | Notes |

|---|---|---|---|

| Electron Emission | Filament heat (mA) | Free electrons | Controlled by tube current |

| Electron Acceleration | kVp voltage | High-speed beam | Determines X-ray penetrating power |

| X-ray Production | Electron–target impact | X-rays + Heat | <1% X-rays, >99% heat |

| Heat Dissipation | Rotating anode + oil | Thermal management | Prevents anode melting/filament damage |

Critical fact: Overheating accelerates filament evaporation and anode pitting — the root of most tube failures.

4.Common Causes of X-ray Tube Failure

- Filament burnout (most frequent — evaporation + snapping).

- Anode pitting/cracking from repeated localized overheating.

- Bearing wear (rotor seizes → no rotation → instant melt).

- Vacuum loss (slow leaks, glass crazing → arcing).

- Oil issues (leaks, contamination → insulation failure).

Regular warmup procedures, proper technique charts, and cooling system checks significantly extend tube life.

FAQ – Frequently Asked Questions

1. What is the most common cause of x-ray tube failure?

Filament burnout from gradual tungsten evaporation (accounts for ~90% of replacements).

2. Why do diagnostic x-ray tubes use rotating anodes?

To spread heat over a larger surface area, enabling higher power, shorter exposures, and preventing focal track melting.

3. How much energy becomes X-rays vs. heat?

Less than 1% is converted to X-rays; over 99% becomes heat.

5.Conclusion

Mastering x-ray tube parts and functions equips you to produce high-quality images safely, troubleshoot issues early, and extend expensive equipment life. From the cathode filament sparking electron flow to the rotating anode managing extreme heat, every component is interdependent.

Need maintenance tips, tube selection advice, or deeper dives into specific brands/models? Reach out — happy to share diagrams, checklists, or resources!

References

- Radiopaedia: X-ray Tube (radiopaedia.org/articles/x-ray-tube-1)

- Bushberg et al., The Essential Physics of Medical Imaging

- Radiology Key: The X-ray Tube (radiologykey.com/the-x-ray-tube-2)