10 Common Causes of X-Ray Tube Failures

As a seasoned engineer with over a decade of experience in medical imaging equipment maintenance and design, I've witnessed firsthand the critical role X-ray tubes1 play in various applications. From medical diagnostics2 to industrial inspection3, these tubes are the heart of countless systems. Their reliable operation is paramount for accurate imaging, precise detection, and, most importantly, patient safety. A failure in an X-ray tube can lead to not only significant downtime and costly repairs but also potentially compromise the quality of diagnostic results or even jeopardize the functionality of crucial medical devices. Therefore, understanding the common causes of X-ray tube failures is essential for preventing these issues and maximizing the lifespan of these vital components.

This article will delve into the 10 most prevalent causes of X-ray tube failure, providing a comprehensive analysis of their mechanisms, symptoms, and preventative measures. This knowledge can empower engineers, technicians, and medical professionals to proactively address potential problems and maintain the optimal performance of their X-ray systems.

Here's a summarized overview of the 10 common causes we'll be exploring:

| No. | Common Cause | Description | Typical Effect |

|---|---|---|---|

| 1 | Overheating | Excessive thermal load damages anode or cathode components. | Reduced emission, cracks, or open circuit. |

| 2 | Vacuum Leakage | Loss of vacuum integrity inside the tube. | Arcing, unstable output, or complete failure. |

| 3 | Insulation Breakdown | Electrical insulation fails due to aging or contamination. | Short circuits, sparks, or system shutdown. |

| 4 | Cathode Filament Burnout | Filament degradation due to overcurrent or long operation. | No electron emission, tube inoperable. |

| 5 | Anode Surface Erosion | Continuous bombardment leads to pitting or melting. | Lower efficiency, image artifacts. |

| 6 | Arcing Discharge | Sudden discharge due to gas ions or surface defects. | Flashover, vacuum loss, damage to electrodes. |

| 7 | Contamination | Residual gases or particles affect electron flow. | Fluctuating output, noise in imaging. |

| 8 | Seal Failure | Poor metal-ceramic bonding or aging seals. | Vacuum degradation, internal leaks. |

| 9 | Thermal Cycling Stress | Repeated heating/cooling causes micro-cracks. | Deformation or loss of alignment. |

| 10 | Improper Operation | Frequent start/stop or overload use. | Premature failure and reduced tube life. |

Let's examine each of these causes in detail:

1. Overheating

- (1) Cause Mechanism: X-ray production is an inefficient process, with most of the energy converted into heat rather than X-rays. If the heat dissipation mechanisms (e.g., anode rotation, oil cooling) are insufficient, the anode and cathode components can overheat. This excessive thermal load can lead to material softening, deformation, and ultimately, structural failure.

- (2) Manifestation Symptoms: Signs of overheating4 include reduced X-ray output, audible noises from the tube (e.g., cracking), and visible damage such as cracks or warpage on the anode. The system might also trigger thermal overload protection mechanisms, leading to shutdowns.

- (3) Prevention and Improvement: Optimize cooling system performance by ensuring proper oil levels and circulation. Adhere strictly to the tube's duty cycle and thermal loading specifications. Consider upgrading to higher heat capacity or more efficient cooling systems for high-demand applications. Sophisticated monitoring systems capable of predicting tube temperatures is a good path to take.

2. Vacuum Leakage

- (1) Cause Mechanism: Maintaining a high vacuum inside the X-ray tube is crucial for efficient electron acceleration and X-ray production. Leakage, often originating from seals or micro-cracks in the glass or metal housing, compromises this vacuum.

- (2) Manifestation Symptoms: Arcing inside the tube becomes more frequent, X-ray output becomes unstable and erratic, and the tube may eventually fail completely. Specialized vacuum gauges can detect pressure increases within the tube housing.

- (3) Prevention and Improvement: Employ rigorous quality control procedures during manufacturing. Regularly inspect seals and housing for signs of damage or degradation. Implement routine vacuum checks as part of preventative maintenance.

3. Insulation Breakdown

- (1) Cause Mechanism: High voltage is critical for the operation, and robust insulation separates the high-voltage components. Aging, contamination (e.g., oil leaks, dust), or physical damage can compromise the insulation's dielectric strength, leading to breakdown.

- (2) Manifestation Symptoms: Short circuits, sparking, and potentially dangerous electrical discharges can occur. The X-ray system will likely shut down due to fault protection mechanisms. The smell of ozone may be present.

- (3) Prevention and Improvement: Use high-quality insulating materials and proper grounding techniques. Maintain a clean and dry environment around the X-ray tube. Regularly inspect insulation for signs of damage or wear. Regular dielectric testing of the tube is also helpful.

4. Cathode Filament Burnout

- (1) Cause Mechanism: The cathode filament, typically made of tungsten, emits electrons when heated. Overcurrent, prolonged operation at high temperatures, or mechanical stress can cause the filament to degrade and eventually burn out.

- (2) Manifestation Symptoms: Little to no X-ray emission is detectable. The system provides error codes indicating filament failure. Visual inspection (if possible) may reveal a broken or severely eroded filament.

- (3) Prevention and Improvement: Operate the filament within its specified current and temperature range. Use controlled warm-up cycles to minimize thermal stress. Implement filament monitoring to detect degradation early.

5. Anode Surface Erosion

- (1) Cause Mechanism: The anode is bombarded with high-energy electrons, leading to localized heating and surface erosion (pitting or melting). This is especially prominent at small focal point.

- (2) Manifestation Symptoms: Lower X-ray efficiency, image artifacts (e.g., blurring, ghosting), and increased radiation scatter may occur. The anode surface may appear rough or uneven upon inspection.

- (3) Prevention and Improvement: Maximize anode rotation speed for improved heat dissipation. Utilize recommended exposure parameters. Keep track of tube usage and replace the tube at or before the specified maximum accumulated heat load.

6. Arcing Discharge

- (1) Cause Mechanism: Sudden electrical discharge within the tube can be triggered by the presence of gas ions, surface defects on the electrodes, or high-voltage transients.

- (2) Manifestation Symptoms: Flashover events, vacuum loss (if the arc damages the tube housing), and damage to the electrodes may result. Audible snapping or crackling noises may accompany the discharge.

- (3) Prevention and Improvement: Ensure a high vacuum within the tube during manufacturing. Implement surge protection measures in the power supply. Maintain clean electrode surfaces.

7. Contamination

- (1) Cause Mechanism: Residual gases or particles within the tube can interfere with electron flow and X-ray production. Contamination can originate from outgassing of components or leaks in the vacuum system.

- (2) Manifestation Symptoms: Fluctuating X-ray output, increased noise in imaging, and unstable tube operation.

- (3) Prevention and Improvement: Use high vacuum pumping and bakeout procedures during manufacturing to remove contaminants. Minimize the introduction of contaminants during operation.

8. Seal Failure

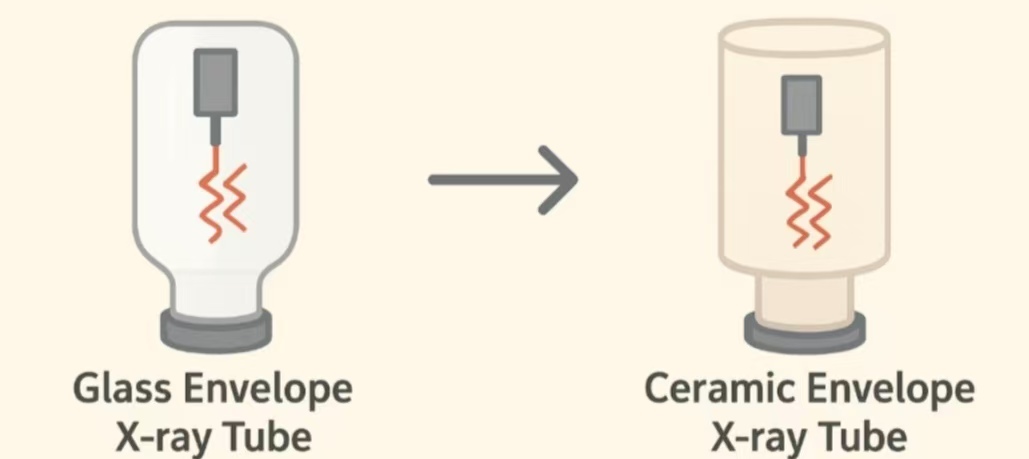

- (1) Cause Mechanism: The seals that maintain the vacuum within the tube can fail due to poor metal-ceramic bonding, aging, or mechanical stress.

- (2) Manifestation Symptoms: Vacuum degradation, internal leaks, and eventual tube failure. Specialized leak detectors can identify seal failure5s.

- (3) Prevention and Improvement: Implement rigorous quality control procedures for seal manufacturing. Use appropriate bonding techniques. Avoid mechanical stress on the seals during installation and operation.

9. Thermal Cycling Stress

- (1) Cause Mechanism: Repeated heating and cooling cycles cause thermal expansion and contraction, leading to micro-cracks and material fatigue, mostly at the tungsten target of the x-ray tube.

- (2) Manifestation Symptoms: Deformation or loss of alignment of internal components, eventually leading to degradation or complete tube failure.

- (3) Prevention and Improvement: Use gradual heating and cooling cycles to minimize thermal gradients. Keep the tube temperature relatively stable. Proper heat management and cooling strategies help lower such stress.

10. Improper Operation

- (1) Cause Mechanism: Frequent start/stop cycles, exceeding maximum tube ratings (KV, mA), or operating outside of specified parameters can accelerate tube degradation and failure.

- (2) Manifestation Symptoms: Premature tube failure, reduced tube life, and decreased X-ray output.

- (3) Prevention and Improvement: Adhere to the manufacturer's recommended operating procedures and duty cycles. Provide comprehensive training for operators. Monitor tube usage and flag potential misuse. Use appropriate protocols and settings for different clinical situations.

Conclusion

X-ray tube failures can have significant consequences, impacting system performance, increasing costs, and potentially affecting patient care or industrial process efficiency. By understanding the underlying mechanisms behind the 10 common causes outlined in this article, and by proactively implementing the recommended prevention and improvement strategies, users and maintenance personnel can minimize the risk of failures, extend the lifespan of their X-ray tubes, and ensure the continued reliable operation of their critical imaging or detection systems. Ultimately, a proactive approach to X-ray tube maintenance is a worthwhile investment that yields significant returns in terms of performance, cost savings, and overall system reliability.

Explore expert insights on maintaining X-ray tubes to ensure optimal performance and longevity. ↩

Learn how X-ray tubes enhance medical diagnostics and improve patient outcomes. ↩

Discover the importance of X-ray tubes in industrial inspection and quality control. ↩

Explore the detrimental effects of overheating on X-ray tube performance. ↩

Understand the serious consequences of seal failure and how to prevent it. ↩