5 Reasons for High Surface Strength in Metallized Alumina

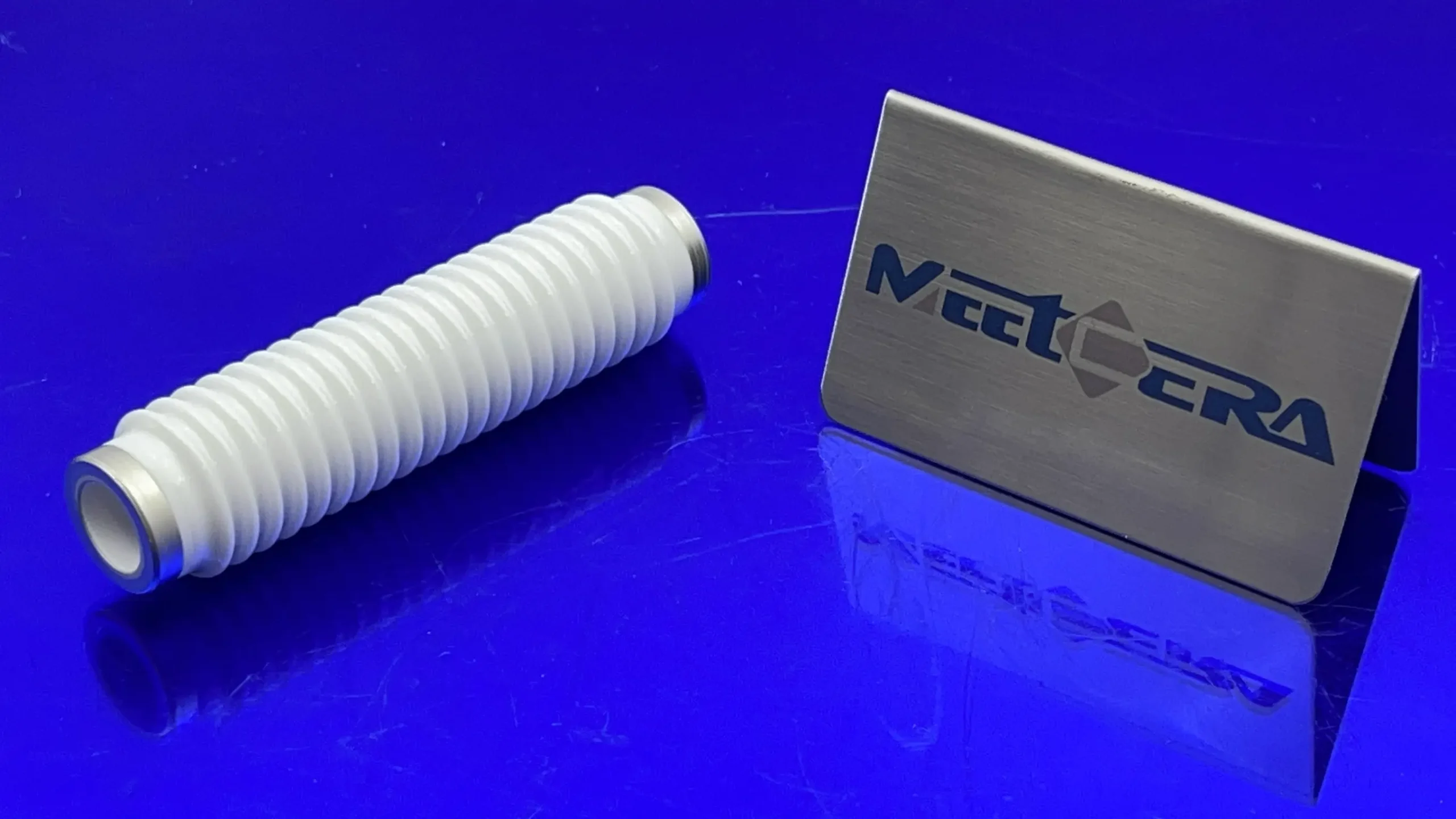

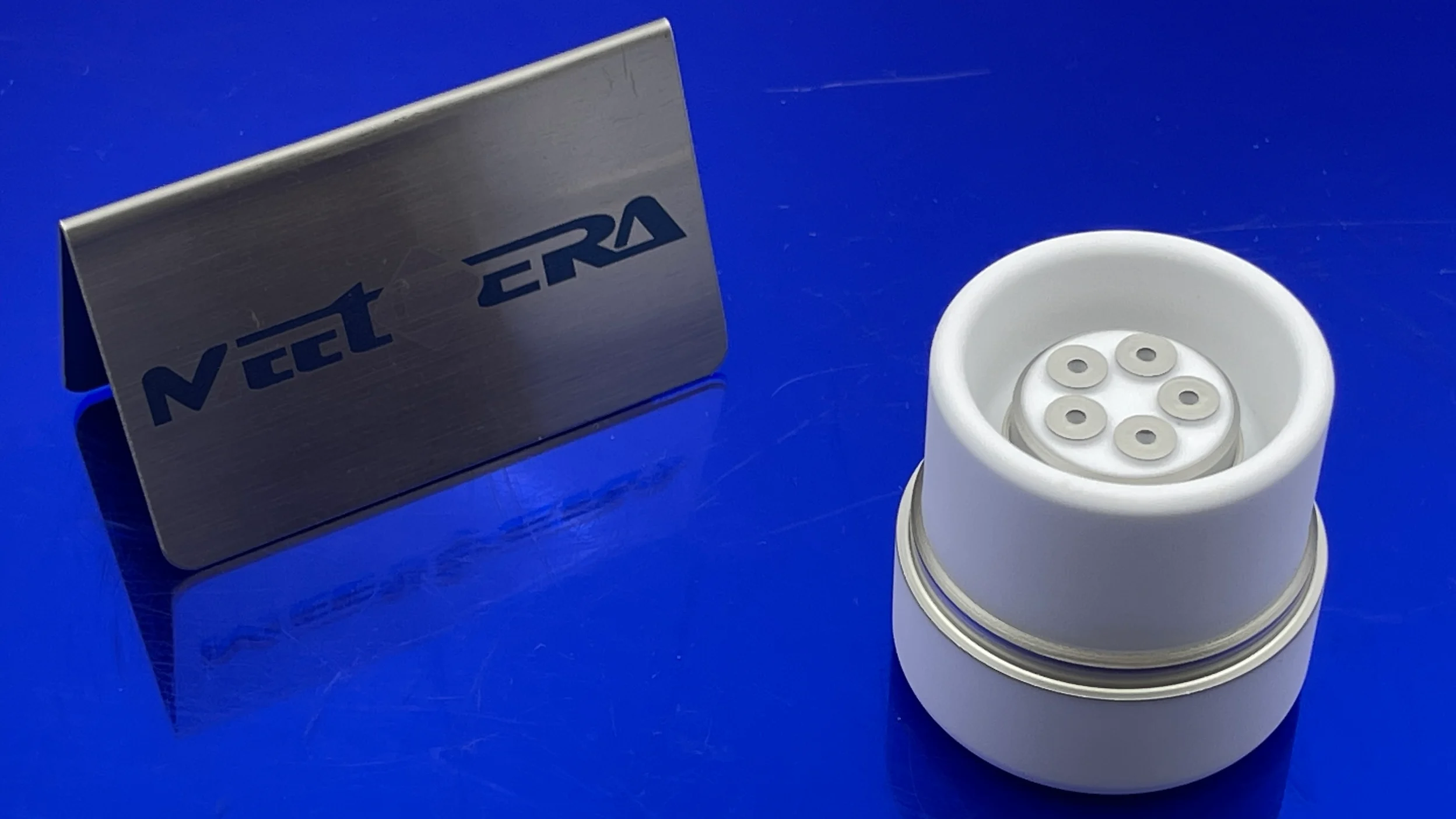

Metallized alumina ceramics are widely used in vacuum tubes, power semiconductors, aerospace feedthroughs, and medical implants because they combine ceramic hardness with reliable metal bonding.

But what truly makes the surface so strong — even under thermal cycling, mechanical stress, and harsh environments?

Here are the 5 decisive factors that determine high surface strength and long-term reliability.

1. Exceptional Intrinsic Strength of High-Purity Alumina Substrate

The foundation is the alumina (Al₂O₃) itself — one of the hardest and strongest oxide ceramics commercially available.

- Vickers hardness ~18–22 GPa (far above most metals and alloys)

- Compressive strength typically >4000 MPa

- Fine-grained, high-density microstructure (HIP or high-purity ≥99.5–99.9%) minimizes defects

This rigid base resists scratching, wear, and plastic deformation, providing an inherently strong platform before any metallization is applied.

2. Extremely Strong Ceramic-Metal Interfacial Bonding

High surface strength would be meaningless if the metallization layer delaminates under load.

Modern Mo-Mn (molybdenum-manganese) metallization + Ni plating creates:

- Chemical bonding via spinel phase (MnAl₂O₄ interlayer ~50–100 nm)

- Mechanical interlocking through controlled glass phase penetration

- Tensile adhesion strength often >80–100 MPa (some processes exceed 120 MPa)

This bond transfers stress efficiently and prevents peeling during thermal shock or vibration.

Explore our range of precision metallized ceramic components featuring optimized Mo-Mn base layers and Ni/Au plating for demanding applications.

For more on Mo-Mn metallization advancements and their role in achieving reliable alumina-metal joining (including interfacial mechanisms and future prospects), see this comprehensive open-access review: Joining alumina to metals: Technologies, challenges, and future prospects for high-performance structures (Journal of the European Ceramic Society, 2025).

| Bonding Method | Typical Adhesion (MPa) | Thermal Cycles (-55°C ↔ +150°C) |

|---|---|---|

| Conventional thick-film | 30–50 | 200–500 |

| Optimized Mo-Mn | 80–120 | >1000 (no delamination) |

| Active metal brazing | 60–100 | 800–1500 |

3. Smart Management of Thermal Expansion Mismatch

CTE mismatch between alumina (~8.1 ppm/°C) and metals can generate destructive stresses.

Engineered solutions include:

- Matching metals: Mo (5.8), W (4.5), Kovar (5.1–5.5)

- Graded interfaces or buffer layers

- Controlled heating/cooling rates + residual stress <20 MPa (via FEM prediction)

Result: survives extreme thermal cycling (e.g., 700°C ↔ -269°C in fusion applications) without interface cracking.

For detailed insights into interfacial reactions that help mitigate thermal mismatch stresses in alumina-metal joints (including brazing and filler effects), refer to this study: Microstructure and seal strength relation in the Molybdenum-Manganese glass metallization of alumina ceramics (Materials Science and Engineering, 1985 – foundational reference still widely cited). (Note: Recent works build on these mechanisms for modern reliability.)

4. Outstanding Resistance to Environmental Attack

Surface strength degrades quickly if corrosion, oxidation or chemical erosion occurs.

Metallized alumina excels because:

- Alumina itself is nearly immune to acids/alkalis (except HF)

- Mo-Mn + Ni/Au plating provides excellent corrosion barrier

- No galvanic corrosion in most electrolytes

Real-world examples: 10+ years in offshore H₂S/NaCl environments, 15-year implantable device service life.

5. Dense, Hermetic Interface with Near-Zero Porosity

A truly strong surface requires continuity — no voids, no weak points.

Advanced metallization achieves:

- Helium leak rate <5×10⁻¹² mbar·L/s (exceeds NASA & MIL specs)

- Interface continuity >98.5% (EBSD mapping)

- Porosity <0.005% (mercury porosimetry)

This hermetic, monolithic-like structure distributes loads evenly and dramatically boosts reliability under pressure, vacuum, or combined stresses.

Research on bonding strength and dense interfacial mechanisms in metallized alumina substrates (including adhesion values and microstructure effects): Surface resistivity and bonding strength of atmosphere plasma sprayed copper‐coated alumina substrate (Journal of the American Ceramic Society, 2020). (While focused on plasma spray, the principles of strong, dense ceramic-metal interfaces align closely with Mo-Mn processes.)

6.Quick Summary Table – 5 Factors at a Glance

| # | Factor | Main Contribution to Surface Strength | If Missing, Typical Failure Mode |

|---|---|---|---|

| 1 | Alumina intrinsic strength | Provides rigid, wear-resistant base | Surface wear / cracking |

| 2 | Robust interfacial bonding | Prevents delamination & stress transfer | Peeling / bond failure |

| 3 | Thermal stress management | Survives wide temperature swings | Interface cracks from cycling |

| 4 | Environmental resistance | Maintains properties in harsh conditions | Corrosion / bond degradation |

| 5 | Hermetic dense interface | Ensures structural continuity & load sharing | Leakage / localized stress concentration |

Conclusion

The exceptional surface strength of metallized alumina ceramics is not accidental — it results from carefully engineering all five factors together. At Meetcera, we optimize material selection, Mo-Mn process parameters, and quality control to deliver metallized components with industry-leading adhesion, thermal reliability, and lifetime performance.

Need custom metallized alumina parts with proven >90 MPa interface strength and >1000 thermal cycles reliability?

→ Browse our full selection of metallized ceramic products or [contact our engineering team for specification support and samples].