Can Metallized Ceramics Be Brazed with Beryllium Windows?

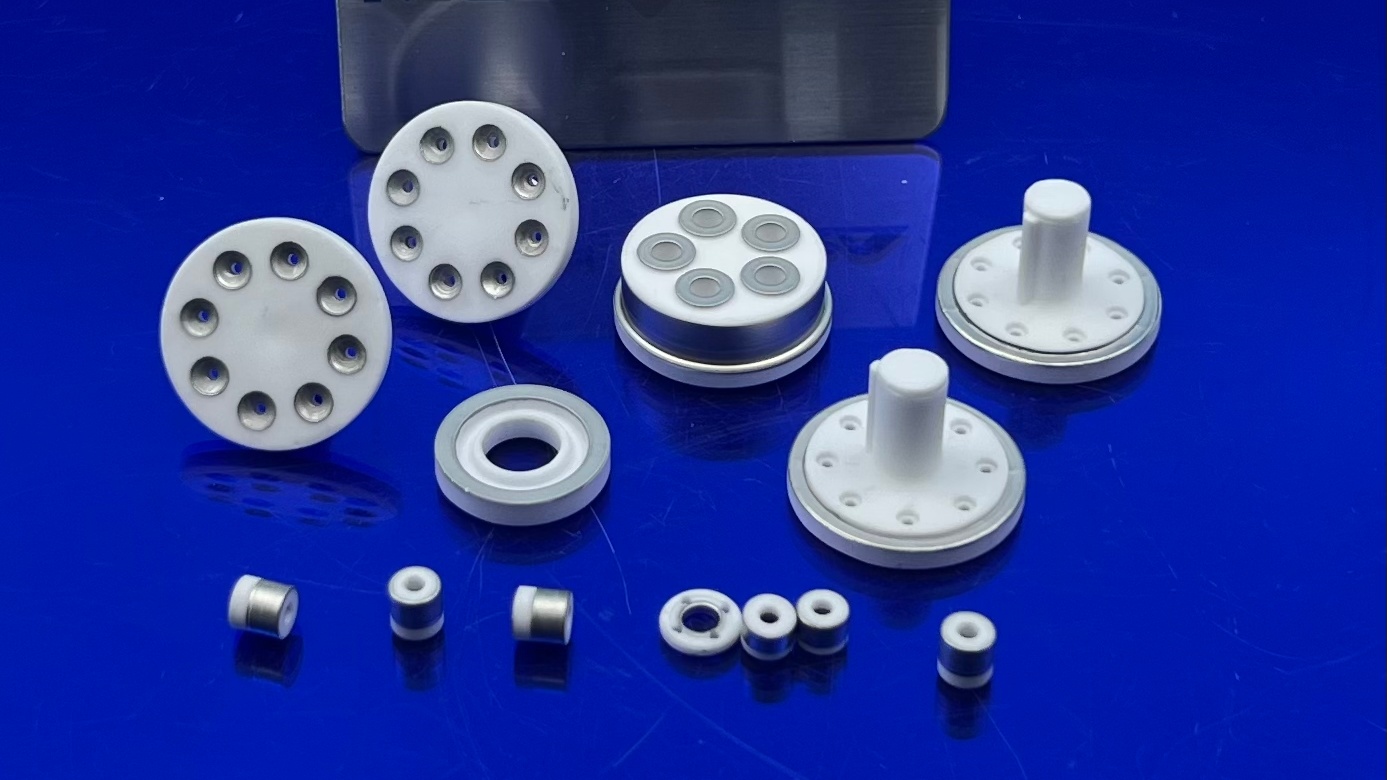

Bridging the gap between dissimilar materials often requires innovative joining methods. Brazing emerges as a strong contender. The connection of metallized ceramics to beryllium windows1 presents unique challenges. Let's explore if brazing offers a reliable solution.

1. What Challenges Arise When Brazing Metallized Ceramics to Beryllium Windows?

Joining metallized ceramics2 to beryllium windows presents several intricate challenges. These difficulties primarily stem from the significant disparity in material properties. The critical differences between their thermal expansion coefficients3 and chemical reactivity can induce substantial stress. This stress concentration jeopardizes joint integrity, potentially leading to premature failure during thermal cycling, especially in extreme temperature environments.

Beryllium's inherent toxicity necessitates stringent handling protocols. Strict adherence to safety guidelines, including specialized ventilation and protective equipment, is paramount during handling and processing to safeguard personnel. Furthermore, the high melting point of ceramics necessitates precise temperature management during brazing. Overheating can irrevocably damage the materials. Selecting the appropriate brazing alloy is paramount. This selection significantly influences joint strength, long-term reliability under operational stress, and the minimization of residual stresses. The formation of brittle intermetallic compounds must also be prevented. Yes, the challenges are significant, demanding meticulous process control and adherence to stringent safety protocols.

2. Why is Brazing Metallized Ceramics to Beryllium Windows Considered a Viable Solution?

Brazing provides unparalleled control over the joining process. This precise control is crucial for maintaining dimensional accuracy and preserving the material integrity of these highly sensitive components. The process enables the creation of robust, hermetic seals. These seals are vital for numerous high-tech applications. These applications demand leak-tight enclosures to ensure proper operation and safeguard long-term functionality. Brazing accommodates intricate designs and complex geometries. This design freedom offers exceptional flexibility in manufacturing specialized components tailored to meet specific and often demanding performance criteria.

Brazing minimizes induced stress, thereby preventing cracking or deformation. This is especially important for inherently brittle materials like ceramics and beryllium. It establishes a favorable equilibrium between joint strength and ductility. This balance ensures the joint can effectively withstand mechanical loads and thermal cycling. These conditions are routinely encountered in demanding operational environments. Consequently, brazing becomes the preferred method for applications where unwavering reliability is of utmost importance. Yes, brazing constitutes a dependable method for joining these dissimilar materials while upholding both structural integrity and operational functionality, ensuring consistent and reliable performance in critical applications.

3. How Does the Brazing Process Impact the Final Joint Properties?

The brazing process exerts a considerable influence on the ultimate mechanical and thermal characteristics of the joint. This influence directly impacts its long-term performance and overall reliability. The specific brazing alloy employed plays a pivotal role, defining joint attributes such as strength, corrosion resistance, thermal conductivity, and its ability to withstand specific operational stresses, including those stemming from vibration, pressure, and chemical exposure. Precise temperature control is paramount. Temperature directly affects the diffusion of the brazing alloy into the base materials, impacting bonding strength, the resultant microstructure, and the potential formation of undesirable intermetallic compounds.

Proper surface preparation4 is an indispensable step in achieving optimal wetting and ensuring strong adhesion of the brazing alloy5 to both the ceramic and beryllium surfaces. Thorough cleaning to remove contaminants is essential. Thoughtful metallization facilitates a receptive bonding surface, which may include applying thin-film coatings specifically formulated to promote enhanced adhesion. A meticulously executed process culminates in a robust and dependable joint, inherently capable of withstanding operational stresses and adverse environmental factors, thereby extending the lifespan and optimizing the performance of the entire assembly. Yes, a carefully controlled brazing process is pivotal for attaining desired joint properties and guaranteeing enduring durability, long-term performance, and consistent reliability under operational conditions.

4. What Are the Key Considerations for Successful Brazing?

Successful brazing necessitates a meticulous assessment of numerous factors. This careful evaluation mitigates potential issues and ensures a robust, long-lasting joint. Primarily, material compatibility must be considered. A comprehensive understanding of the chemical and physical interactions among the ceramic, beryllium, and selected brazing alloy is critical. The alloy composition must be chemically compatible, preventing the formation of brittle intermetallic compounds. These compounds have the potential to catastrophically weaken the joint. Also, the alloy's melting temperature must be suitable for both base materials.

Vacuum brazing is frequently favored. This preference stems from its ability to minimize oxidation. By minimizing oxidation of the materials and the brazing alloy, vacuum brazing6 creates a clean, strong joint distinguished by enhanced metallurgical properties. Precise temperature control is essential to circumvent issues. It is necessary to prevent overheating or damage to either material during the brazing cycle while concurrently ensuring proper diffusion and bonding of the brazing alloy. Fixturing is incredibly important. It supports precise alignment during brazing. This prevents distortion of the assembly, facilitates controlled joint thickness, and ensures dimensional accuracy in the completed assembly. Yes, meticulous planning, execution, and validation are essential for achieving consistently successful brazing outcomes and ensuring sustained long-term reliability. This necessitates the involvement of highly skilled technicians and the application of meticulously optimized process parameters.

| Alloy Composition | Melting Range (°C) | Key Characteristics |

|---|---|---|

| Ag-Cu-Ti | 780-880 | Good wetting, high strength, reactive, suitable for ceramic brazing |

| Au-Ni | 950-1000 | Excellent corrosion resistance, high-temperature use, good for beryllium |

| Al-Si | 577-585 | Low-temperature brazing, good for specific applications, cost-effective |

5. What Are the Common Applications of Brazed Metallized Ceramics and Beryllium Windows?

Brazed assemblies fulfill critical needs in various industries. They provide essential functionality in specialized equipment by leveraging their unique combination of material characteristics. X-ray tubes and detectors depend on these assemblies for their ability to afford vacuum-tight seals. These seals simultaneously facilitate efficient X-ray transmission through the beryllium window. High-power microwave devices utilize these joints for their outstanding electrical and thermal conduction qualities. These qualities are essential for effective heat dissipation and dependable signal transmission.

Aerospace applications gain significant benefits. The high strength-to-weight ratio and resistance to extreme environmental conditions make these assemblies suitable for structural components in harsh environments. Vacuum systems mandate hermetic seals in research and industrial settings. These seals ensure the integrity of high-vacuum environments. They are essential for the success of sensitive experiments and the proper operation of specialized equipment. The wide range of uses emphasize the adaptability of these assemblies. They also highlight the importance of the joining process. Demanding technical environments demand both high performance and strict quality control. Yes, the applications extend across numerous high-tech sectors, each demanding specific performance characteristics. The successful and reliable operation of these applications hinges on stringent quality assurance standards and meticulous process control.

6. What Future Advancements Can We Expect in Brazing Techniques for These Materials?

Future research will focus on enhancing brazing alloys. This will improve the efficiency and reliability of brazing processes. Nano-brazing and active brazing are particularly promising. They enhance bond strength at lower temperatures. This outcome reduces residual stresses. This also enables the joining of even more sensitive materials. These advancements lead to better control over the brazing process. This minimizes defects. This also augments the mechanical and thermal properties of the joint.

Advanced process monitoring using sensor and feedback systems is becoming more commonplace. This monitors joint quality in real-time, optimizing brazing parameters continuously and detecting potential issues. Predictive modeling optimizes brazing parameters. It also simulates the brazing process. This is done to anticipate joint characteristics and pinpoint the best process settings. This reduces reliance on trial-and-error. These innovations will boost reliability while simultaneously cutting manufacturing This will also expand the application of brazed components. Yes, the field is constantly evolving thanks to constant innovation leading to enhanced and more robust solutions.

In conclusion, brazing metallized ceramics to beryllium windows is feasible and widely used. This is of course if materials, processes, and safety are considered. Future research is needed to drive further improvements and broaden applications.

-

Discover the applications of beryllium windows in high-tech industries and their unique properties. ↩

-

Learn about metallized ceramics to appreciate their role in advanced manufacturing and technology. ↩

-

Understand the importance of thermal expansion coefficients in ensuring joint integrity during thermal cycling. ↩

-

Discover the significance of surface preparation in ensuring strong adhesion and optimal joint performance. ↩

-

Learn about brazing alloys to understand their critical role in achieving strong and reliable joints. ↩

-

Explore vacuum brazing to understand its benefits in minimizing oxidation and enhancing joint quality. ↩