Can Metallized Ceramics Be Brazed with Beryllium Bronze?

Joining dissimilar materials stands as a pivotal aspect of modern engineering. This capability enables the creation of sophisticated designs. It allows engineers to strategically leverage the unique properties of each constituent material. Brazing, a meticulous joining process, utilizes a carefully selected filler metal to establish a robust metallurgical bond. This offers a versatile and reliable solution in a wide array of applications. The efficacy of brazing hinges critically on a comprehensive understanding of the specific characteristics of the materials involved, as well as the nuances of the brazing process itself. This article delves into the feasibility of brazing metallized ceramics with beryllium bronze. We will cover material properties, advantages, challenges, key process steps, real-world applications, and essential quality control measures.

1. What Distinguishes Beryllium Bronze from Beryllium Windows in Brazing? Understanding Detailed Material Property Variations.

Beryllium bronze1, an alloy primarily composed of copper with strategic additions of beryllium (typically ranging from 0.5 to 2% by weight), exhibits key and distinct differences when compared to pure beryllium windows. The subtle, yet impactful, difference in composition significantly influences the final material properties, that are very important to the success of the brazing process.

**Beryllium bronze demonstrates markedly superior mechanical strength, increased hardness, and enhanced ductility compared to pure beryllium windows. Alloying with copper significantly increases its machinability, simplifying the fabrication of geometrically complex shapes and intricate designs. Unlike beryllium windows, beryllium bronze typically possesses lower thermal conductivity, and a higher coefficient of thermal expansion; these are critically important parameters to meticulously manage during the brazing process to prevent stress-induced failures. Furthermore, beryllium bronze provides enhanced corrosion resistance due to the protective presence of copper, offering superior protection as compared to the vulnerability of pure beryllium in beryllium windows. These important differences strongly influence the selection of brazing techniques, precise parameter selection, and ultimately, the long-term reliability and performance of the brazed joint.

2. Why Opt for Beryllium Bronze over Alternatives? Rationales and Specific Use Cases Deeply Explored.

Several distinct advantages support choosing beryllium bronze over alternative materials in specific engineering applications, aiming to maximize value. It strikes a crucial balance between essential mechanical strength and satisfactory thermal conductivity. Beryllium bronze serves as an attractive alternative to pure beryllium, especially where stringent vacuum-tight seals aren't absolutely required for system functionality.

**The enhanced machinability of beryllium bronze greatly simplifies fabrication of complex parts, often resulting in significantly reduced manufacturing costs compared to working with more brittle or difficult-to-machine materials. In scenarios requiring a suitable blend of thermal and electrical conductivity paired with dependable structural integrity, beryllium bronze presents itself as a cost-effective and viable option. It finds application in integrated housings and heat sinks. These may not demand expenses of high-cost materials. This is where beryllium bronze offers an optimized balance of properties with reduced cost.

3. Brazing Alloy Selection: How Does it Dictate Joint Integrity, Performance Outcomes, and Longevity?

Selecting the right brazing alloy will ensure a robust, reliable, and durable joint capable of withstanding diverse operating conditions, and prolonging its lifespan. This meticulous choice greatly impacts the final joint's strength, thermal and electrical conductivity, resistance to corrosion, and sustained performance under mechanical stress. These considerations are paramount for achieving optimal results.

**Achieving effective wetting of the metallized ceramic surface and ensuring proper adhesion to the beryllium bronze are paramount for establishing a strong metallurgical bond during brazing. Employing a brazing alloy2 whose melting temperature remains lower than the melting points of both base materials helps prevent unwanted degradation or distortion during the brazing cycle. Active brazing alloys incorporating titanium can dramatically improve wetting characteristics. It allows for direct brazing while eliminating the prior need for specialized and often costly metallization processes. Selecting the most suitable brazing alloy helps ensure a lasting, durable joint that competently withstands the demands of its intended application.

4. What are the primary Hurdles, Failure Mechanisms, and Mitigation Strategies when Brazing these Materials?

When brazing any material combination, several challenges and potential failure mechanisms must be addressed carefully. High or low temperatures, environmental conditions, and inherent material properties always introduce potential complications to the brazing process. Certain challenges can prove quite difficult to manage.

**Material differences, such as any substantial mismatch in coefficients of thermal expansion (CTE), may result in significant internal residual stresses within the brazed joint, particularly during the cooling process. Over extended periods, such accumulation of stresses may cause cracking, overall distortion, or even catastrophic joint failure. A carefully calibrated and meticulously controlled heating and cooling cycle serves as an effective mitigation strategy. The formation of brittle intermetallic compounds at the interface between the brazing alloy and the base materials poses another potential threat. Choosing an appropriate alloy and precisely controlling the brazing process are key to minimizing the risk of intermetallic compound formation.

Table 1: Comparison of Properties Impacting Brazing

| Property | Beryllium Bronze | Metallized Ceramic | Typical Brazing Alloy |

|---|---|---|---|

| Thermal Conductivity | 105-130 W/m·K | 20-30 W/m·K | 100-200 W/m·K |

| Thermal Expansion | 17 x 10-6 /°C | 6-8 x 10-6 /°C | 15-20 x 10-6 /°C |

| Tensile Strength | Up to 1400 MPa | 200-300 MPa | 300-500 MPa |

| Electrical Conductivity | 22-30% IACS | Very Low | 15-50% IACS |

| Melting Point | 870-1040°C | > 2000°C | 600-900°C |

| Density | 8.2-8.9 g/cm3 | 3-6 g/cm3 | 8-10 g/cm3 |

5. Where Does Brazing shine? Exploring a Broad Spectrum of Applications Suited for Brazed Material Combinations.

Brazing excels in a wide range of applications that capitalize on carefully integrated material attributes. These attributes come together strategically during the material construction process. High-power electronics and sensor technology benefit from thermal management capabilities and durable material combinations. Beryllium bronze can effectively regulate temperatures and maintain the extended performance life of brazed ceramic components in demanding operational.

**Aerospace designs benefit significantly from the optimized strength-to-weight ratio and effective thermal regulation offered by brazed material combinations. When correctly implemented and meticulously executed, brazed connections provide exceptional reliability. It delivers consistent, dependable performance in challenging operating contexts where long-term accuracy is paramount. Furthermore, brazing is frequently used in the manufacturing of medical devices. It will provide strong, biocompatible joints.

6. What Critical Steps, Advanced Techniques, and Stringent Quality Controls Ensure Brazed Joint Reliability Throughout Manufacturing?

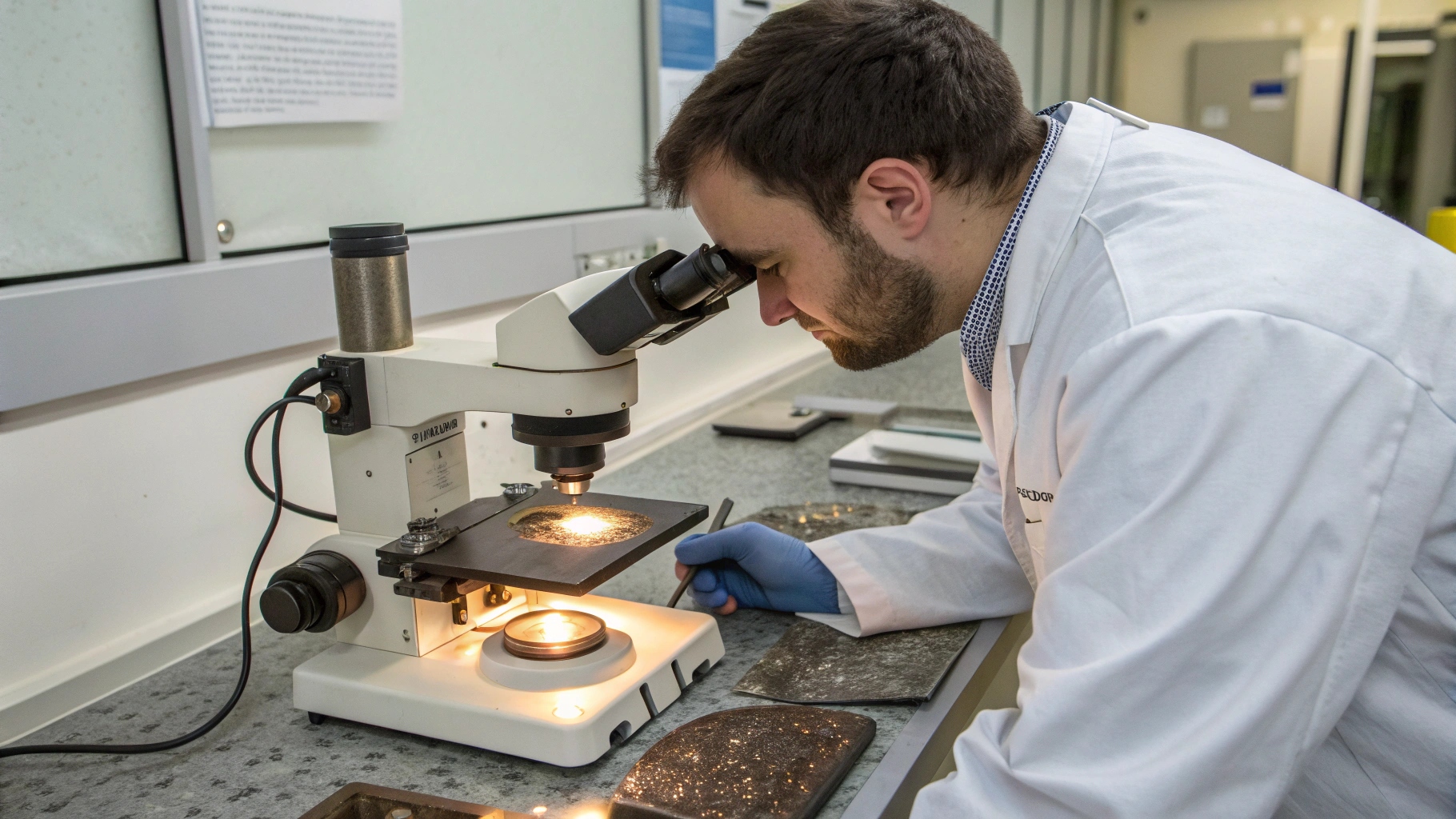

The surface preparation meticulously performed directly impacts the achievable joint quality. Meticulously cleaning surfaces to be bonded minimizes the introduction of foreign contaminants. The surface contaminants may prevent a firm bond.

**Vacuum furnaces play a significant role in mitigating oxidation during the brazing process3, thereby significantly increasing joint robustness and its long-term reliability. Comprehensive testing, including non-destructive evaluation (NDE) techniques, is vital for comprehensively evaluating joint integrity after brazing. Post-braze testing is essential to confirm reliability in real-world applications without any signs of premature failure. These thorough evaluations diligently reveal any potential weaknesses or defects promptly.

In conclusion, effective brazing of metallized ceramics4 with beryllium bronze, although demanding, can be achieved by carefully heeding the materials' unique properties,. It provides benefits that include combined strength, precise temperature control, and weight optimization. Every stage necessitates rigorous planning and diligent execution to ensure superior long-term performance.

Explore the unique properties of Beryllium bronze that make it a preferred choice in various engineering applications. ↩

Gain insights into the selection criteria for brazing alloys to ensure optimal joint performance. ↩

Understanding the brazing process can enhance your knowledge of material joining techniques and their applications. ↩

Discover the significance of metallized ceramics in modern engineering and their diverse applications. ↩