Ceramic-to-Metal Brazing in X-Ray Tubes: A Deep Dive

The X-ray tube is often hailed as the heart of medical CT scanners and industrial non-destructive testing (NDT) equipment. Inside this core component lies an extremely brutal working environment: ultra-high vacuum (UHV), voltages soaring to hundreds of kilovolts (kV), and immense thermal loads generated instantly.

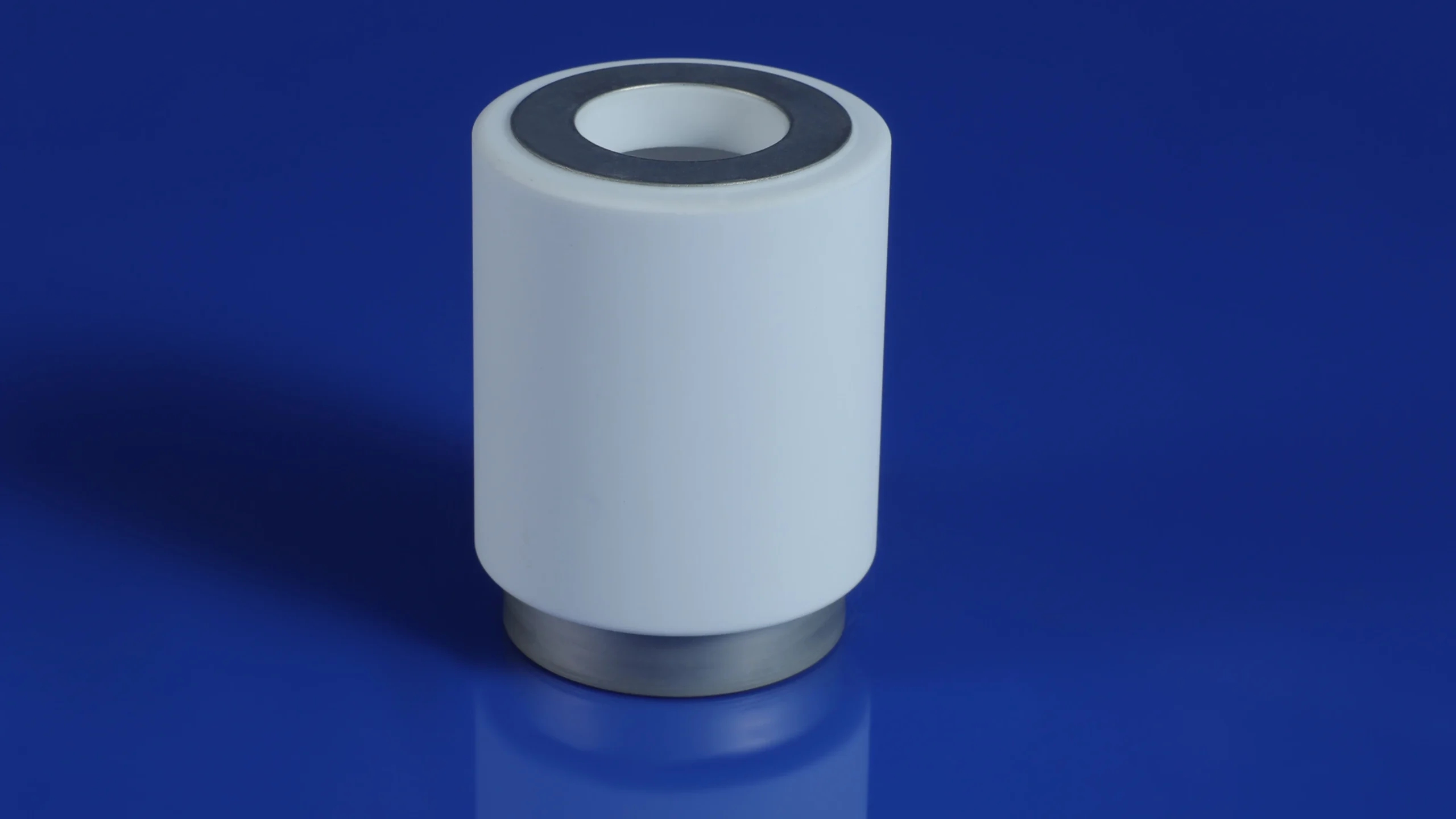

To ensure equipment operates stably under these extreme conditions, traditional glass sealing technologies have gradually fallen short of modern demands. Ceramic brazing in X-ray tubes (Ceramic-to-Metal Brazing) has emerged as the solution. It is not merely a process for connecting insulators to conductors, but the key to constructing a robust defense line between high voltage and vacuum.

1. Core Challenge: Why Choose Alumina Ceramic?

In early X-ray technology, glass was the primary insulating material. However, as modern CT scanning speeds increase and industrial inspection power requirements rise, mechanical strength and thermal shock resistance have become critical.

Alumina ceramic X-ray tube sealing assemblies have become mainstream because they outperform borosilicate glass across critical physical properties. According to research cited by the National Institute of Standards and Technology (NIST) on Advanced Ceramics, alumina’s structural stability under extreme thermal loads makes it the premier choice for vacuum electronic devices.

Material Performance Comparison: Ceramic vs. Glass

| Key Performance Indicator | 99.5% Alumina Ceramic (Al₂O₃) | Borosilicate Glass | Advantage Analysis |

|---|---|---|---|

| Mechanical Strength | Very High (> 300 MPa) | Low (Fragile) | Withstands high G-forces during CT rotation |

| Thermal Conductivity | Excellent (~30 W/m·K) | Poor (~1.2 W/m·K) | Rapidly dissipates waste heat from the anode |

| Dielectric Strength | > 15 kV/mm | ~ 10-15 kV/mm | Allows higher voltage in smaller spaces |

2. Structural Analysis: The Art of High Voltage Feedthrough Design

The primary function of an X-ray tube high voltage feedthrough is to safely introduce external high-voltage power into the vacuum chamber while maintaining absolute vacuum sealing and electrical insulation.

To balance the significant differences in the Coefficient of Thermal Expansion (CTE) between ceramics and metals, designers often refer to the International Union for Vacuum Science, Technique and Applications (IUVSTA) standards for vacuum system connections. By using transition materials like Kovar, engineers ensure that the seal remains hermetic even after thousands of thermal cycles.

3. Key Processes: Vacuum X-Ray Tube Brazing & Leak Rate Control

To manufacture a qualified X-ray tube component, the brazing process is the determinant of success. Currently, mainstream processes fall into two categories:

- Mo-Mn (Moly-Manganese) Metallization: The most mature industrial solution. By sintering a metal layer onto the ceramic surface, the ceramic is rendered "solderable."

- AMB (Active Metal Brazing): Uses fillers containing active elements (like Ti) that react directly with the ceramic.

Regardless of the process, quality inspection after vacuum X-ray tube brazing is stringent. Leak rates must typically be lower than . For complex medical CT tubes, packaging technologies must align with the International Electrotechnical Commission (IEC) 60601 safety standards for medical electrical equipment, ensuring long-term reliability and radiation safety.

4. Endurance in Extreme Environments: Radiation & Aging

Beyond high voltage and vacuum, the interior of an X-ray tube is subject to intense ionizing radiation. Long-term exposure to X-rays can cause lattice damage in ordinary ceramic materials, forming "color centers" which lead to degraded insulation performance. Therefore, high-purity alumina (99.5%+) is essential for resisting radiation aging and extending the tube's service life.

5. Industry Practice: From Medical to Industrial

- Medical X-ray Ceramic Components (CT Tubes): In CT scanners, the brazing seam must possess extremely high shear strength to prevent displacement during high-speed rotation.

- Industrial NDT Applications: Designs here focus on external ruggedness and moisture resistance, often employing thickened ceramic walls and special surface glazing.

6. Future Outlook

As imaging technology evolves, X-ray tubes are trending toward Higher Voltage (>150kV) and Miniaturization. This presents new challenges:

- Optimized Geometry: Using advanced modeling to withstand higher voltages within limited spaces.

- New Materials: Composites like Zirconia Toughened Alumina (ZTA) are being tested to enhance mechanical toughness.