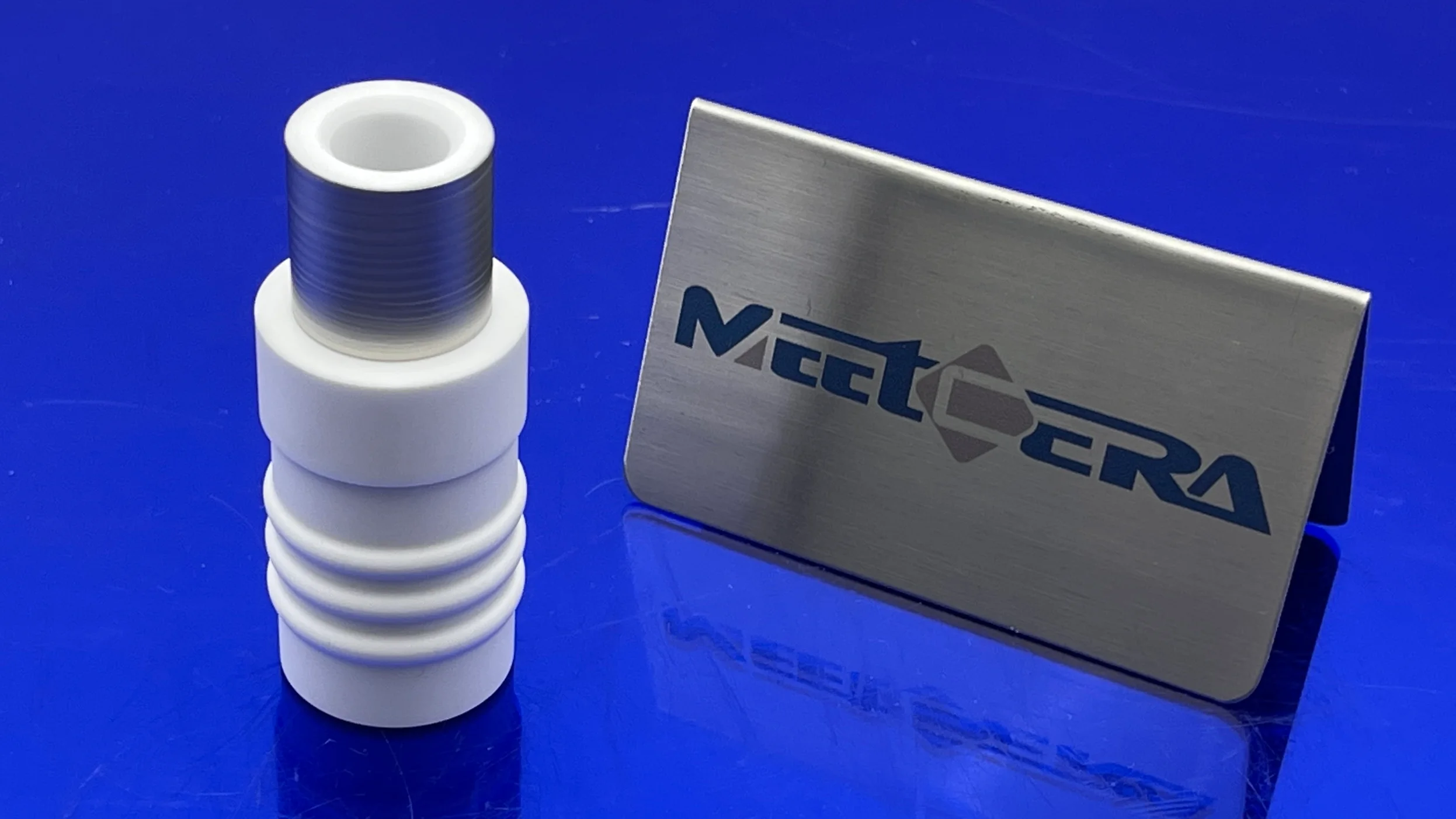

How to Choose the Best Metal Ceramic Suppliers

In 2025, aerospace, electronics, and medical industries require ultra-reliable ceramic-to-metal components. The right supplier is critical for performance under extreme conditions—wrong choice risks failure, recalls, or downtime.

This guide evaluates suppliers on 8 key criteria (technical expertise, manufacturing, quality, application fit, design support, communication, reputation, cost scalability) plus 2025 trends like sustainable sourcing and digital twins, to help you select hermetic, durable partners with minimal risk.

1. Proven Technical Expertise and Experience in Ceramic Metallization

Do potential metal ceramic suppliers demonstrate deep knowledge in ceramic-to-metal brazing, handling challenges like CTE mismatch and high-temperature interactions?

Without specialized expertise, suppliers may overlook subtle material science issues, resulting in weak bonds or premature failures. For instance, in aerospace applications, improper metallization can lead to hermeticity loss at 400°C deltas.

Based on our 20+ years at Meetcera, suppliers with focused R&D in high-reliability sectors outperform generalists by 50% in failure rate reduction.

2. Advanced Manufacturing Capabilities and Process Controls

Do they invest in state-of-the-art equipment and rigorous controls for consistent, high-quality ceramic-to-metal assemblies?

In 2026, with rising demands for precision, lacking tools like vacuum furnaces or AI-monitored sintering can cause batch inconsistencies. This is critical for applications requiring 0.1μm tolerances.

| Equipment Type | Key Specifications | Why It Matters for Reliability |

|---|---|---|

| Vacuum Furnace | ±3°C uniformity at 1800°C | Prevents oxidation in brazing, ensuring 99.99% hermeticity |

| Sputtering System | 0.05μm layer precision | Optimizes adhesion for high-vibration environments |

| AI Process Monitor | Real-time parameter adjustment | Reduces defects by 30%, per industry reports from ASM International |

| Laser Profilometer | 0.01μm resolution | Verifies surface roughness for optimal bonding |

Sustainable practices, like energy-efficient furnaces, are a bonus in today's eco-conscious market.

3. Robust Quality Assurance and Testing Protocols

Are their quality systems certified and testing methods comprehensive enough to catch hidden defects in metal ceramic components?

Even advanced processes can falter without verification. In medical devices, undetected voids could compromise sterility, leading to regulatory issues.

Reliable suppliers achieve Six Sigma yields, as seen in our Meetcera projects where we've reduced field failures by 70% through environmental simulations.

4. Alignment with Your Specific Application Needs

Can they deliver for harsh environments, like ultra-high vacuum or corrosive settings in electronics or aerospace?

Generic suppliers often fail in niche demands, such as 2026's push for bio-compatible materials in implants.

| Performance Metric | Top Metal Ceramic Suppliers | Average Providers | Improvement |

|---|---|---|---|

| Thermal Shock Resistance | 300k cycles at ΔT 500°C | 100k cycles | +200% |

| Hermeticity in Corrosive Media | 99.9999% (7σ) | 99.9% (3σ) | 900ppm better |

| Scalability for High-Volume | 1M units/year with digital tracking | 100k units/year | 10x faster ramp-up |

| Sustainability Index | 85% recycled materials | 40% | 112% greener |

A case study: We partnered with a medical firm to develop brazed feedthroughs surviving 1,000 sterilization cycles, exceeding industry averages.

5. Comprehensive Design and Engineering Support

Do they collaborate on optimizing designs for manufacturability and reliability in ceramic-to-metal joining?

Inadequate support leads to redesign loops, inflating costs by 20-30%. With 2025's CAD/CAE integrations, expect proactive simulations.

Our Meetcera experts have co-designed 100+ assemblies, cutting client development time by 40%.

6. Effective Communication and Customer Service

Is their team responsive and transparent, from quoting to post-delivery?

Poor communication causes 25% of supply chain delays, per Supply Chain Dive reports. In a globalized 2026 market, multilingual support is key.

Proactive suppliers build trust, as evidenced by our 98% client retention rate.

7. Strong Track Record and Industry Reputation

Have they consistently delivered for similar clients, backed by testimonials?

A spotty history signals risks. Research via platforms like LinkedIn or industry forums.

8. Cost-Effectiveness and Scalability for Future Growth

Do they offer competitive pricing with flexibility to scale as your needs evolve?

In 2025, with inflation and tariffs, balance cost with value. Scalability prevents bottlenecks in ramp-ups.

9.Common Questions on Choosing Ceramic Metallization Manufacturers

- What is CTE mismatch?

Coefficient of Thermal Expansion difference between materials, which can cause stress—mitigated by expert design. - How does sustainability fit in?

Look for suppliers using low-emission processes to meet 2025 regulations. - What's the cost range?

Varies from $5-500 per unit, depending on complexity.

10.Conclusion

Partnering with the best metal ceramic suppliers ensures your products thrive in demanding environments. At Meetcera, we're committed to excellence—contact us for a free consultation on your ceramic-to-metal needs. For more, explore our ceramic metallization case studies or sustainable manufacturing blog