4 Key Factors to Achieving Robust Metallized Ceramic Surface Strength

As a seasoned materials scientist specializing in ceramic metallization, it’s been my privilege to witness firsthand the evolution of this field and the increasing demands placed upon metallized ceramic components. With over a decade dedicated to unraveling the complexities of ceramic-metal interfaces, I’ve contributed to projects ranging from advanced radar systems to cutting-edge medical devices. My expertise encompasses everything from fundamental materials characterization to the development of innovative processing techniques. Through countless experiments, simulations, and collaborative efforts, I’ve developed a deep understanding of what truly matters when pursuing durable and reliable metallized ceramic surfaces. This article is a culmination of that experience, offering practical guidance and actionable insights to help you achieve your metallization goals.

Strong adhesion between a metal layer and ceramic substrate is paramount due to being a crucial role of overall reliability and performance for components. Weak interfacial bonds can act as the weakest link, leading to delamination, crack propagation, and catastrophic failure. This can further compromise the efficiency, safety, and longevity of entire systems. Creating a strong metallized ceramic surface needs the consideration of key parameters. Let’s explore these in more detail:

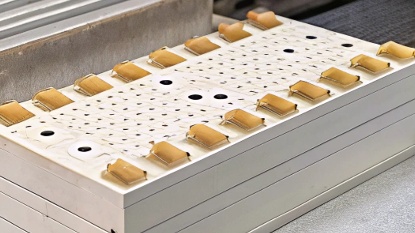

1. Surface Preparation1: The Cornerstone of Metallization Success

Effective is effective; This is a key consideration when creating high-quality metallized ceramic products. The fundamental condition of the ceramic surface is usually one that is crucial in influencing the metallization process. Contaminants, variations in surface roughness, and the presence of minute amounts of micro-cracks can significantly challenge formation strength.

| Surface Preparation Technique | Description | Impact on Strength | Specific Considerations | Typical Equipment |

|---|---|---|---|---|

| Cleaning (Solvent/Plasma) | Removes organic residues, oils, fingerprints, and other surface contaminants that hinder wetting and adhesion. Solvents like acetone, isopropyl alcohol, and deionized water are common. Plasma cleaning uses ionized gas to eliminate contaminants. | Essentially optimal for efficient metallization and adhesion bonding between materials surfaces that can lead stronger bond. | Consider solvent compatibility with ceramic and ensure proper contaminant removal. Optimize plasma cleaning to avoid surface damage. | Ultrasonic cleaners, plasma cleaners (RF or microwave), vapor degreasers |

| Surface Roughening2 (e.g., Sandblasting, Etching) | Create surface topography to increase area for better bonding and mechanical interlocking systems into substrates material for improved bonds. Sandblasting uses abrasive particles from pressured air to give roughen surface with etching that employs chemical solutions that dissolve ceramic surfaces | Increases mechanical adhesion; excessive roughening causes stress concentrations and micro-cracks. | Control grit size and pressure in sandblasting; select etching solutions carefully for roughness without damage. An example includes HF to etch silica-based ceramics. | Sandblasting cabinets, wet etching stations with temperature control |

| Activation (e.g., Plasma Treatment3, Chemical Activation) | Modifies ceramic chemistry to enhance wettability and reactivity. Plasma treatment introduces functional groups with chemical activation that uses solutions for forming reactive species. | Promotes optimal bonding as well as improving wettability of ceramic surfaces. | Plasma treatment requires parameter tailoring that is based from particular ceramic substrate materials as well processing to optimize reactions when creating an enhanced mechanical interlocking network for strong bonds along high surfaces. | Plasma reactors (barrel or parallel plate), chemical wet benches with controlled atmospheres |

| Polishing | Achieving smooth, defect-free surfaces before starting metallization | Reduces stress that lead cracks formation. | Precise control needed with abrasive and controlling each parameter related pressure. Series of finer abrasives typically achieve smooth surfaces. | Polishing machines with automated feed systems and slurry control |

Surface quality serves as a base for more layers and determines the interface. The technique is often tailored and optimized for specific materials.

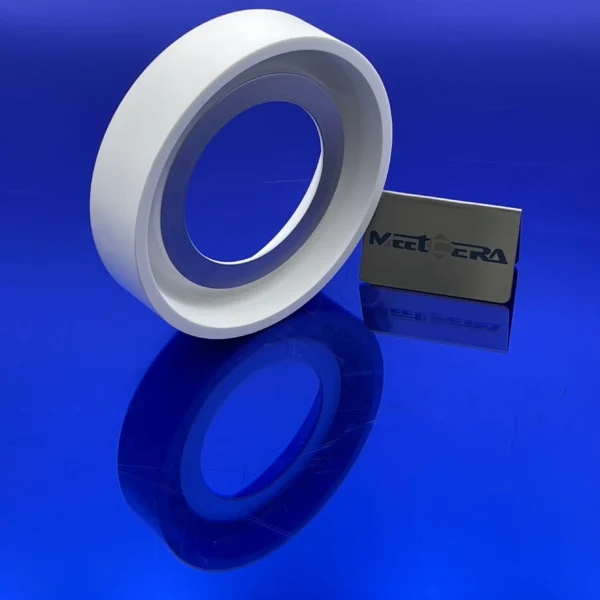

2. Metallization Method4: Choosing the Right Process for Bonding

The metallization methods provide choices for cost efficiency processing and strength.

| Metallization Method | Description | Advantages | Disadvantages | Applications | Key Parameters |

|---|---|---|---|---|---|

| Thick Film (Screen Printing) | Metal ceramic paste which composes metals with additional binders. The paste is then screened onto ceramic substrates and sintered for high bonding capabilities due to network of metal particles interacting. | High volume processing method with low costs. Patterning with flexible options for ceramic. | Lower resolution and higher surface roughness with limited materials and potential porosity. | Resistors and sensors, including interconnects within circuitries. | Paste viscosity, screen mesh size, firing profile |

| Thin Film (Sputtering, Evaporation) | Thin layers are plated onto ceramic under an intense vacuum environments with the use of bombarding ions ejecting atom and depositing material layers. | High levels of precision with good quality of metals being created at interfaces that requires good thickness monitoring. | Compared to other low throughput volume levels can create materials slower while additional costs that may require extra bonding. | Semiconductor sensor device requires layer to complete construction processing of materials. | Deposition rate, target composition, substrate temperature |

| Direct Bond Copper (DBC) | Copper bonds directly to the ceramic substrates at high temps. Bond is created where copper connects with substrates. | This material offers high conductivity for optimal applications with great mechanical interlocking for high strength at higher temperatures that have outstanding reliability. | Being materials it has limitations based on specific composition needs or high levels of temperature to adhere at optimal settings to adhere on surfaces. | Power electronics like automotive application for power LEDs. | Bonding temperature, atmosphere control, surface cleanliness |

| Electroless Plating | Chemicals are used on ceramic layers to plate without external electricity with chemical reactions that uses metals to deposit ions straight onto surfaces | Uniforms that plates great for non conducting surface as a low-cost solution. | Slow plating that is material specific that creates limited processes that may require a series to ensure optimal stability with solution parameters throughout metallization to ensure all specifications meets requirements. | Circuit boards that offers decorative functions | Plating bath composition, temperature control, immersion time |

Choosing the methods depends on application. Thick films for production is efficient, and thin films offers properties for electronics. DBC provides thermal management with electroless that provides economical plating techniques for non-conductive surfaces.

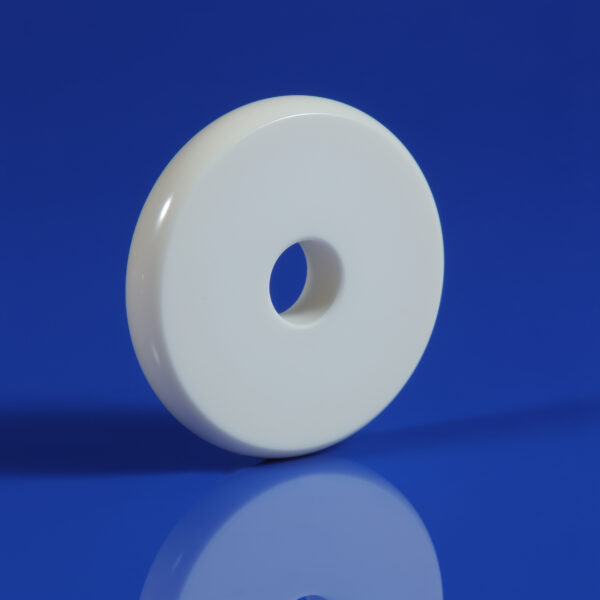

3. Material Selection: Optimizing Material Interactions in System

Selecting ceramics is important, its thermal and chemical properties like its thermal capabilities are important because properties depends on bonding. To avoid premature complications here is a table of materials that can greatly influence bond strength:

| Material Property | Impact | Example Considerations | Mitigation Strategies | Characterization Techniques | |

|---|---|---|---|---|---|

| Thermal Expansion Coefficient (CTE) | Stresses emerge where fluctuation with temperature change, this lead to deboning and cracks | Selecting ceramics that is very similar to substrates so that metals adhere to that temperature when CTE occurs | Layer to that helps ceramics withstand that with geometry design. | Dilatometry, strain gauge analysis | |

| Chemical Compatibility & Interfacial Reactions | Chemical materials need compatibility with ceramic so that bonds are not altered during a process. | Metals and non-metals helps not have reactions with phases. | Diffusion and barriers needs to be implemented for optimal performance. | X-ray diffraction (XRD), transmission electron microscopy (TEM) | |

| Wetting and Interfacial Energy | Wetting requires a strong bond | Select metals that wets good onto ceramic substrate materials so its enhances bonding characteristics | Surface to increase higher energy when ceramic is in operation. | Contact angle measurements, surface energy analysis | |

| Ceramic Grain Size & Microstructure | Fine grains has properties to make it stronger withstand all phases and forces. | By selecting ceramics this helps withstand pores during high operation without stress. | Improves and reduces pore characteristics during operation performance | Microscopy helps find the correct settings for bonding. | Scanning electron microscopy (SEM), atomic force microscopy (AFM) |

Proper material selection ensures compatibility while proper stress is being managed.

4. Post-Processing and Environmental Conditions

Creating layers on surface is an important task so protecting the process can perform its life cycle correctly.

| Factor | Impact | Mitigation Strategies | Example Application | Monitoring Methods |

|---|---|---|---|---|

| Annealing (Stress Relief) | Stresses can create weakness on the surface increasing cracking. Annealing removes stresses for good performance during bond phase. | Optimizing temp is important and how long so that interface are not compromised. | Substrates often use is power modules in performance | Optical microscopy, residual stress measurement |

| Surface Protection (Environmental Barriers) | Metallized surface which creates corrosion. Applying coating is what prevents from harsh damages. | Applying great shielding for harsh damages. | Using great methods and packages to isolate other external environments. | Electrochemical impedance spectroscopy (EIS), salt spray testing |

| Operating Temperature & Thermal Cycling | Great exposures is required for great operations so that is does not cause degradation of bonds on surface. | Select processes that maintain bonds at great operations. | Substrates often create heat to maintain and reduce heat by implementing cooling. | Thermal imaging, temperature sensors |

| Mechanical Loading & Vibration | Vibrations can add stress and high loads leads to bond degradation so processes are exposed to extreme conditions. | Design materials for high vibratory environments and reduce other amplitudes. | Transmissions helps withstand load for great performance. | Vibration testing, finite element analysis (FEA) |

In Conclusion: Achieving robust metallized ceramic surface strength is not simply a matter of following a recipe; it is a holistic engineering endeavor that demands a deep understanding of the complex interplay between materials, processes, and environmental factors. As we’ve explored, meticulous surface preparation lays the essential foundation, ensuring optimal wetting and adhesion. The judicious selection of a metallization method tailored to the specific application is crucial, balancing cost, throughput, and performance requirements. Careful consideration of material compatibility, with particular attention to thermal expansion coefficients, chemical reactivity, and interfacial energy, is paramount to preventing premature failure. Finally, vigilant post-processing and environmental protection measures safeguard the bond against degradation, ensuring long-term reliability.

My years of experience in this field have consistently reinforced the importance of a systems-level approach. Each of these four key factors is interconnected, and a deficiency in any one area can compromise the integrity of the entire metallized ceramic structure. By meticulously addressing each of these aspects, engineers and scientists can unlock the full potential of metallized ceramics, creating high-performance components that excel in even the most demanding environments. Whether you’re designing high-power electronic modules, developing advanced sensors, or innovating in the field of biomedical implants, a thorough understanding of these principles will empower you to achieve superior results and push the boundaries of what’s possible with metallized ceramics. It’s this commitment to comprehensive understanding and rigorous execution that separates success from failure in the pursuit of robust and reliable metallized ceramic surfaces.

-

Surface preparation is foundational for achieving high-quality metallized ceramics, impacting adhesion and overall performance. ↩

-

Surface roughening enhances mechanical interlocking, which is essential for strong bonds in metallized ceramics. ↩

-

Plasma treatment improves wettability and bonding characteristics, crucial for successful metallization. ↩

-

Exploring various metallization methods helps in selecting the best process for specific applications and performance needs. ↩