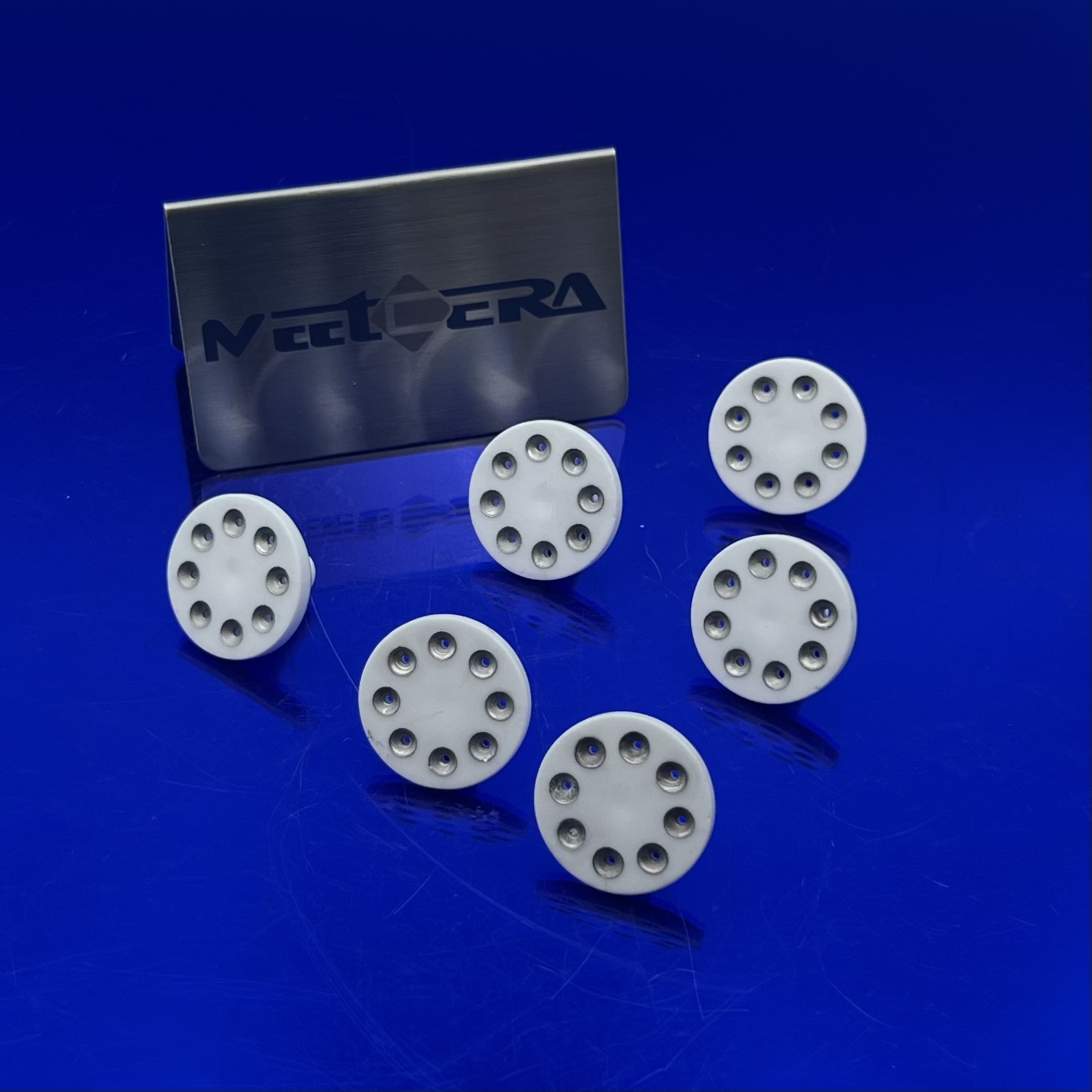

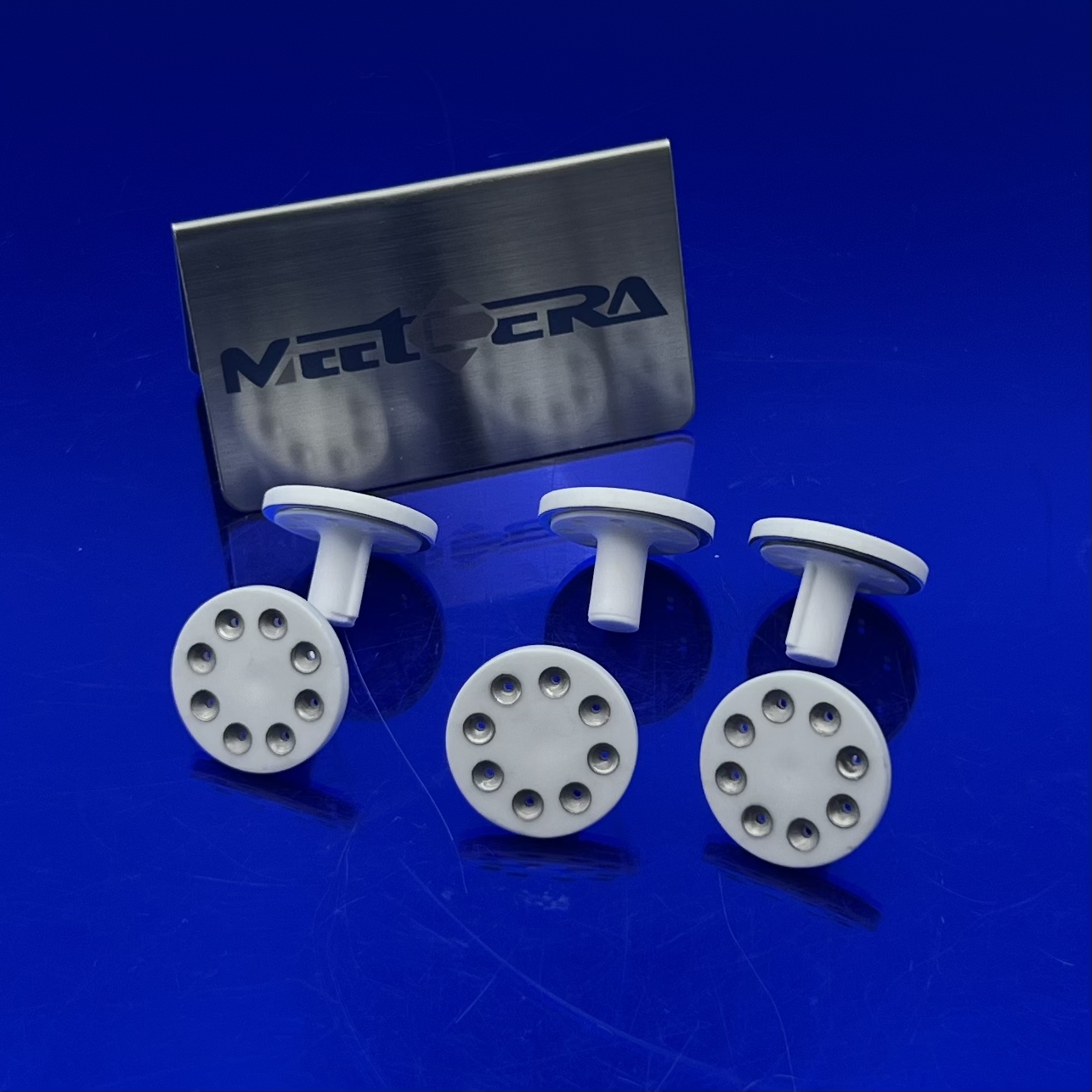

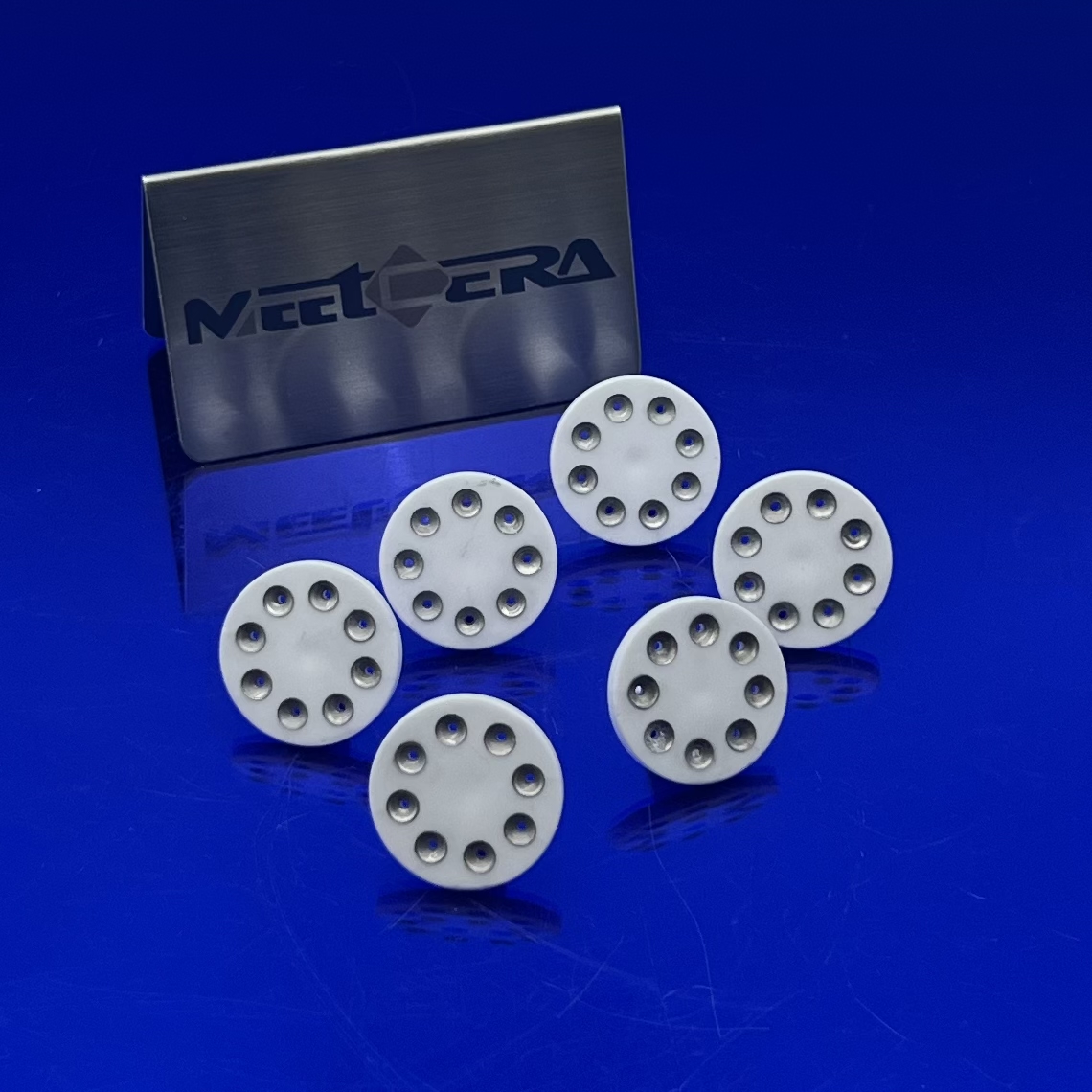

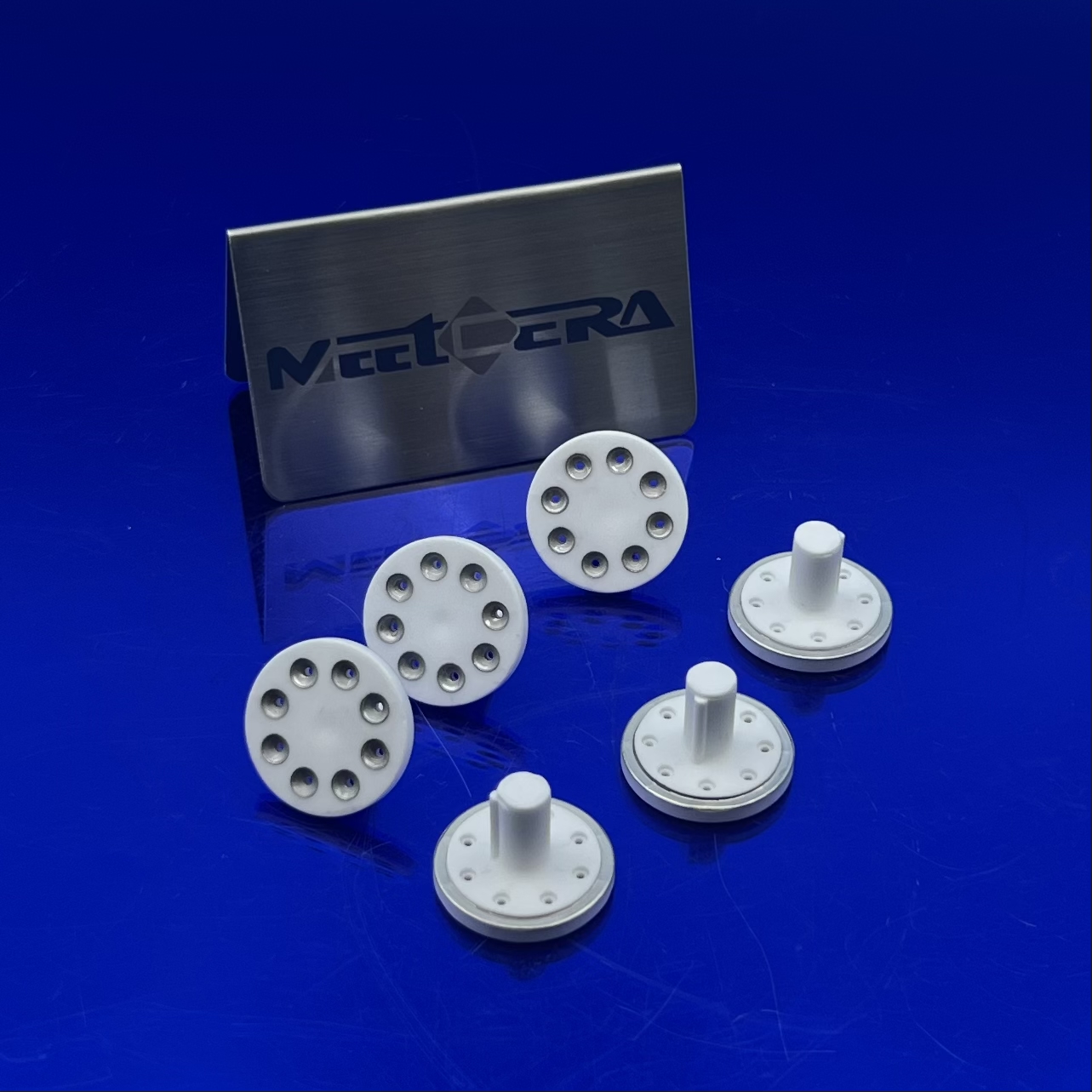

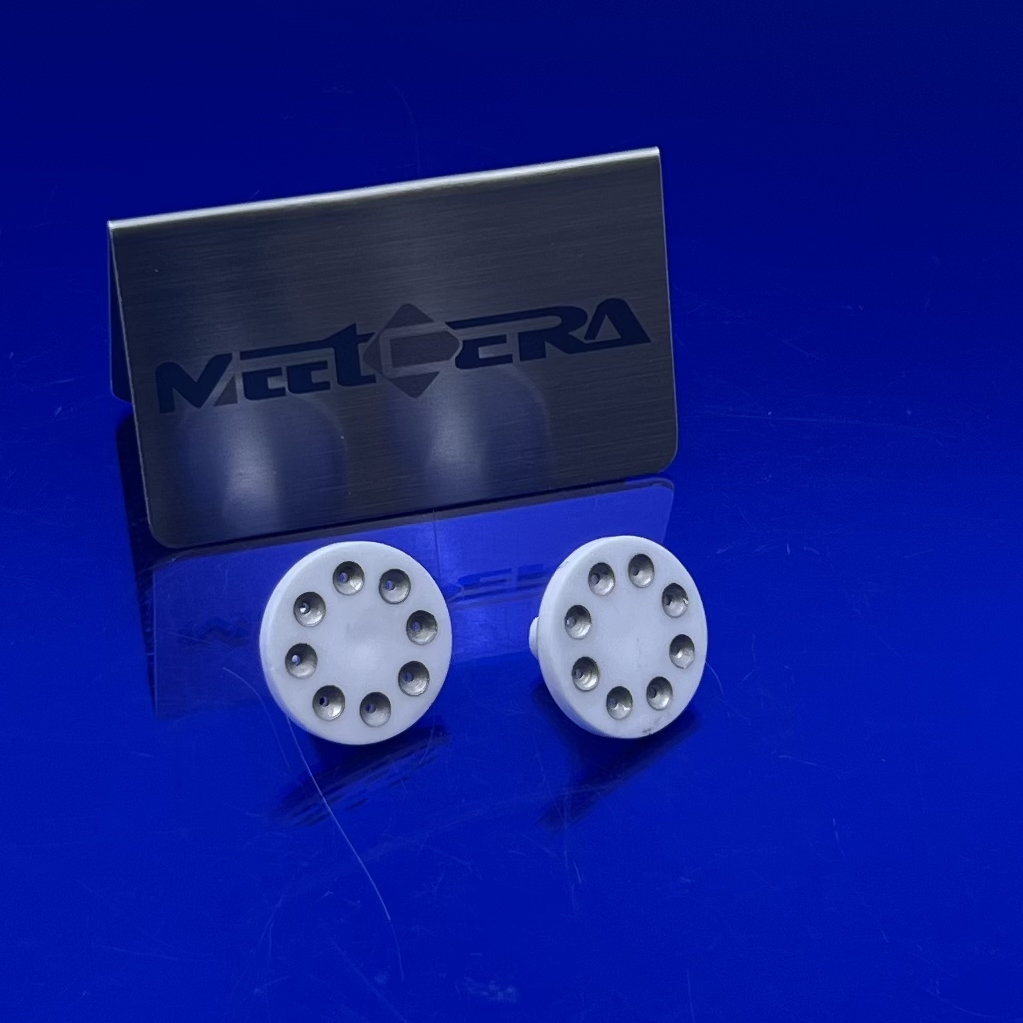

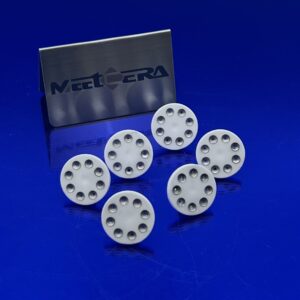

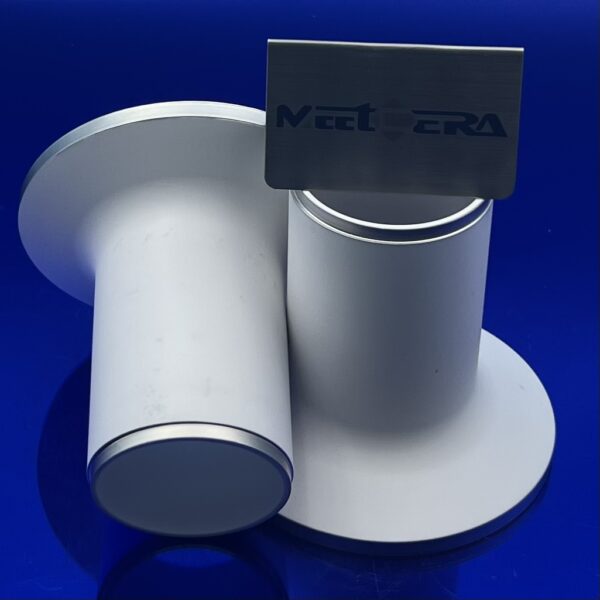

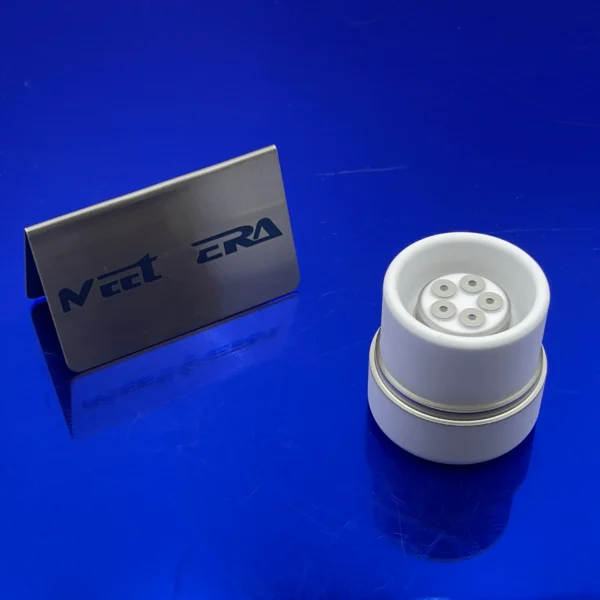

Metallized ceramic components

Product Name | Precision Ceramic Metallization Housings for Relays |

Compositions | 96.0% alumina or 99.5% high purity alumina (Al2O3) |

Metalization | Sintered with Molybdenum & Manganese (Mo+Mn), then Nickel plating |

Mo+Mn Layer | 25 +/-10μm in thickness |

Nickel Layer | 2 -10μm in thickness |

Helium Leak Testing | 1×10-12 Pa·m3/s |

Tensile Strength | ≥800Kg/cm2 |

Material Density | 3.68 - 3.90 g/cm3 |

Tolerance | +/- 0.005mm |

Finishing | Ra 0.02 |

Max. Using Temperature | 1650 oC |

Using Fields | DC Relayer, Fuel Cell Units, New Energy Vehicles, Charging Piles, DC Railway, Electric Forklifts, Electrical Appliance, Electric Products |

Metallized Ceramics Applications:

- Ceramic Feed-through insulators,

- Ceramic Headers,

- Ceramic High-power receptacles,

- Ceramic Insulating discs,

- Ceramic Insulator rings and cylinders,

- Ceramic Precipitator products,

- Ceramic Power switches,

- Ceramic Traveling wave tubes,

- Ceramic Vacuum interrupters,

- Ceramic components for Windows,

- Ceramic Power grid tubes,

- X-ray Ceramic tubes

Metallized Ceramics Joining types:

- Ceramic + Mo/Mn Metallized + plating Ni

- Ceramic + Mo/Mn Metallized + plating Ag

- Ceramic + Mo/Mn Metallized + plating Au

- Ceramic + printing Ag

Special types are available according to customer’s drawings or samples