Vacuum Ceramic Brazing Basics 2026: Hermeticity & Alumina vs AlN

Vacuum electron devices are core components in high-end equipment such as radars, satellite communications, and particle accelerators. Ceramic brazing in vacuum electron devices is the key process for achieving high reliability in these devices. Microwave tubes, traveling wave tubes (TWT), and klystrons operate in high-power, high-frequency environments, imposing extremely stringent requirements on the hermeticity and radio frequency (RF) performance of ceramic-to-metal seals.

As the first article in this series, this piece systematically explains the core performance requirements for ceramic brazing in vacuum electron devices and compares the advantages and disadvantages of alumina and aluminum nitride in high-frequency applications, laying the foundation for subsequent process optimization and application cases.

1. Hermeticity and RF Performance Requirements for Ceramic Brazing in Vacuum Electron Devices

Vacuum electron devices typically need to operate stably in ultra-high vacuum environments (above 10⁻⁶ Pa) over the long term. Therefore, ceramic brazed joints must meet strict hermeticity standards:

- Typical helium mass spectrometer leak rate requirement: < 10⁻⁹ ~ 10⁻¹⁰ atm·cc/s (or Pa·m³/s)

- Maintain vacuum integrity after high-temperature baking (400~600°C)

- Strong resistance to thermal shock and mechanical vibration

In terms of RF performance, brazed joints must achieve low insertion loss, low VSWR, and high power handling capacity:

- Extremely low dielectric loss (tanδ) to prevent high-frequency energy dissipation and heating

- High breakdown voltage, suitable for kilowatt to megawatt power levels

- Good impedance matching to ensure signal transmission efficiency

Other key requirements include CTE (coefficient of thermal expansion) matching, mechanical strength, and compatibility with multiple baking cycles. Common failure modes include interface cracking, virtual brazing leading to leaks, excessive RF loss, etc. These directly constrain brazing process parameters.

For real-world high-reliability applications in vacuum electron devices, components are routinely helium-tested to these levels or better, often achieving <1×10⁻¹⁰ atm·cc/s in production.

2. Selection of Alumina and Aluminum Nitride Ceramics in High-Frequency Applications

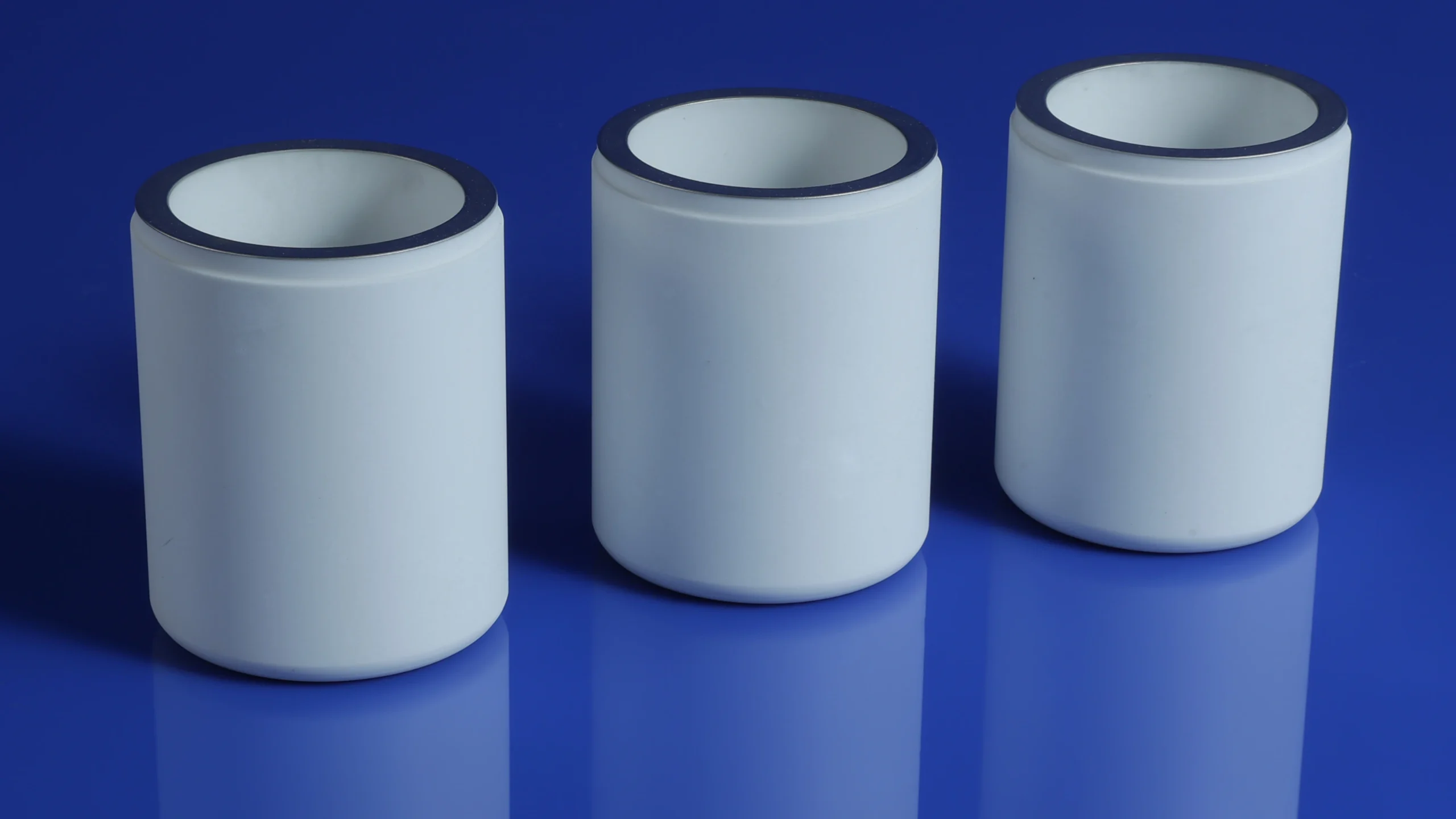

In microwave tube alumina brazing and high-frequency scenarios, alumina (Al₂O₃) and aluminum nitride (AlN) are the two mainstream ceramic materials.

(1) Advantages of Alumina Ceramics:

- High mechanical strength, flexural strength 300~400 MPa

- Low dielectric loss, cost only 1/3~1/5 that of aluminum nitride

- Mature process, widely used in microwave tube alumina brazing and medium-to-low power devices

Alumina remains the benchmark material for RF windows in vacuum tubes. due to its proven performance in high-power microwave applications

(2) Advantages of Aluminum Nitride Ceramics:

- Thermal conductivity up to 170~230 W/m·K (alumina only 20~30 W/m·K)

- Thermal expansion coefficient close to silicon (≈4.4×10⁻⁶/K), better thermal matching

- Lower dielectric constant and loss, suitable for millimeter-wave and high-power-density applications

These superior thermal and dielectric properties make AlN particularly valuable in RF/microwave substrates and high-power scenarios .

(3) Selection Criteria:

- Medium-to-low power, cost-sensitive scenarios (e.g., conventional radar microwave tubes) → Prioritize alumina

- High-frequency, high-power, stringent thermal management scenarios (e.g., satellite TWTs, millimeter-wave klystrons) → Recommend aluminum nitride

- Comprehensive considerations: frequency range, power density, processing difficulty, and budget

3. Conclusion

Mastering hermeticity, RF performance requirements, and ceramic material selection forms the foundation of ceramic brazing in vacuum electron devices. This article provides the material basis for subsequent multi-layer feedthrough processes and low-loss optimization.

The next article will delve into the multi-pin/multi-layer brazing technology for traveling wave tube ceramic feedthroughs. Stay tuned!

4. FAQ

Q. What is the typical hermeticity standard for ceramic brazing in vacuum electron devices?

Usually requires a helium mass spectrometer leak rate ≤ 10⁻⁹ ~ 10⁻¹⁰ atm·cc/s, maintaining high vacuum even after high-temperature baking.

Q. Why must aluminum nitride be chosen over alumina in some high-frequency applications?

Aluminum nitride's thermal conductivity is 5–10 times that of alumina, offering better thermal management, lower dielectric loss, and suitability for high-power-density and millimeter-wave devices.

Q. Which has lower cost: alumina or aluminum nitride?

Alumina typically costs only 1/3–1/5 of aluminum nitride, making it suitable for medium-to-low power, cost-sensitive microwave tube applications.