What Are Metallized Ceramics and How Do They Work?

In high-reliability industries such as aerospace, medical devices, power electronics, and vacuum systems, engineers face a constant challenge: how to achieve strong, hermetic seals1 between ceramic and metal components. These seals must endure thermal cycling2, high pressure, and aggressive environments — all while maintaining electrical insulation.

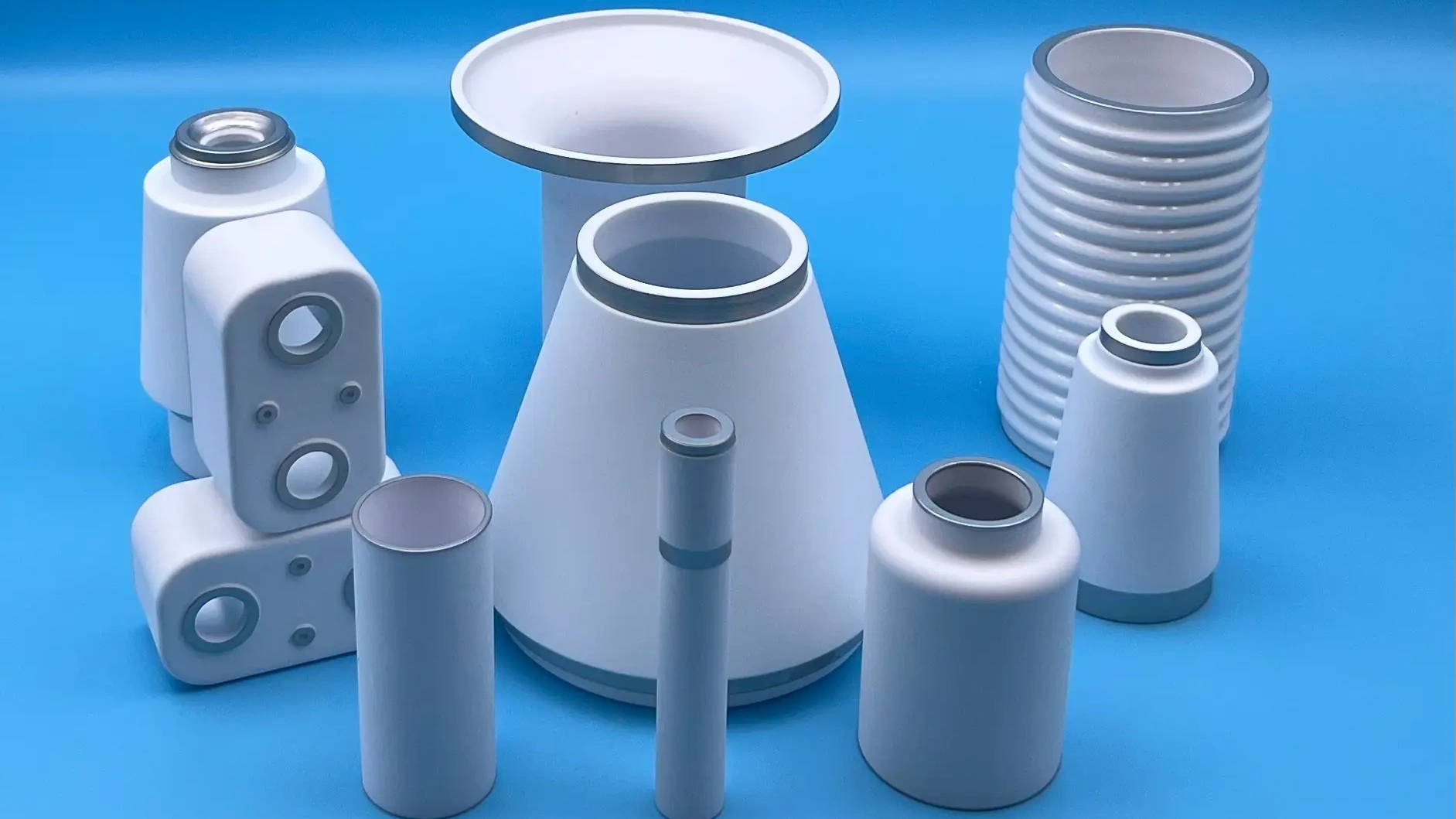

This is where metallized ceramics play a vital role. They combine the electrical insulation and corrosion resistance of ceramics with the conductivity and weldability of metals, enabling ceramic-to-metal assemblies3 that are both mechanically robust and hermetically sealed.

In this guide, we’ll explain what metallized ceramics4 are, how they work, their manufacturing process, materials, applications, and why they are indispensable in today’s most demanding industries.

1. What Are Metallized Ceramics?

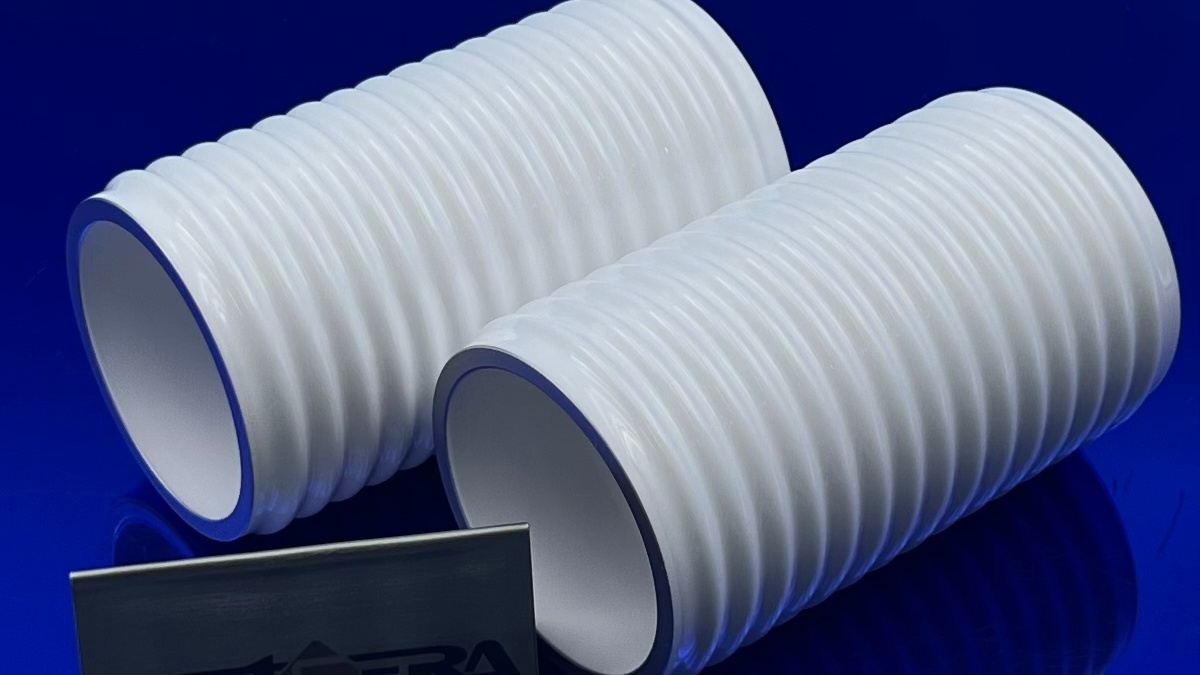

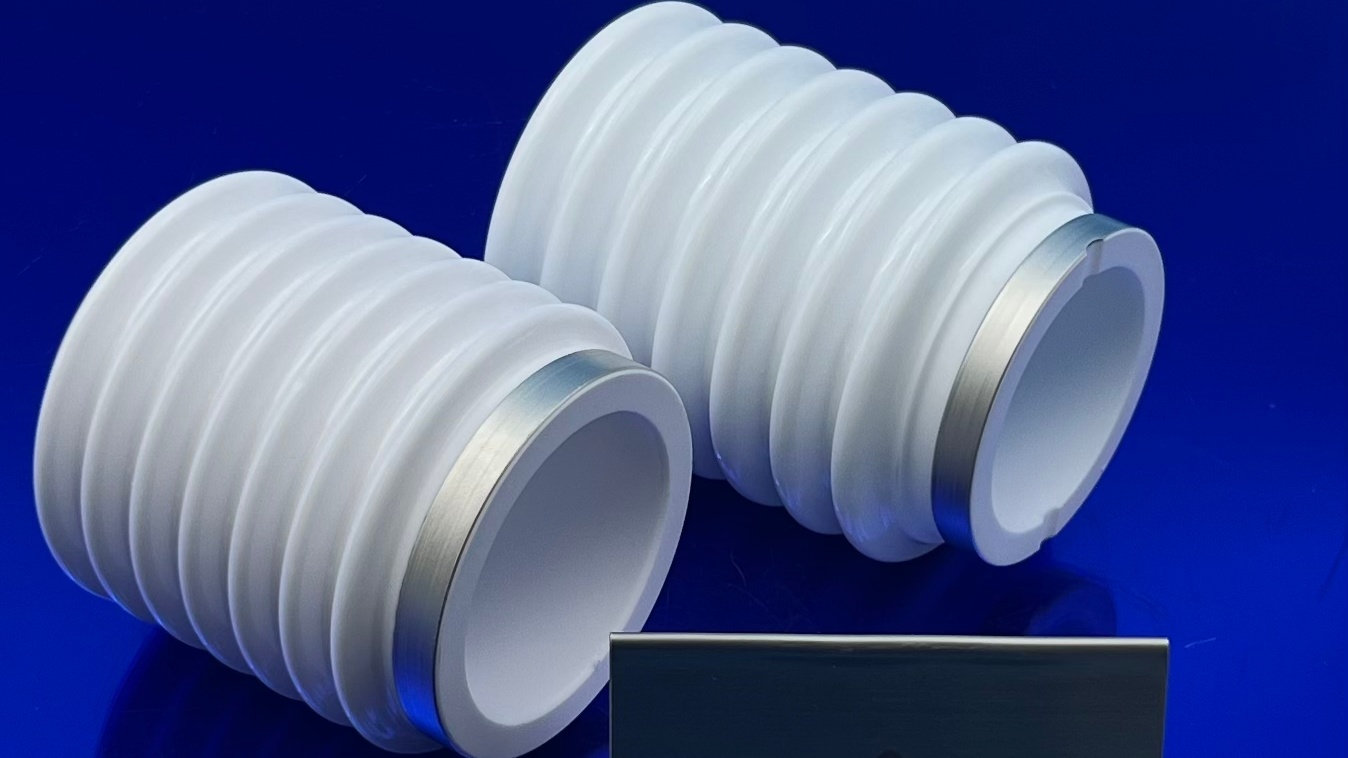

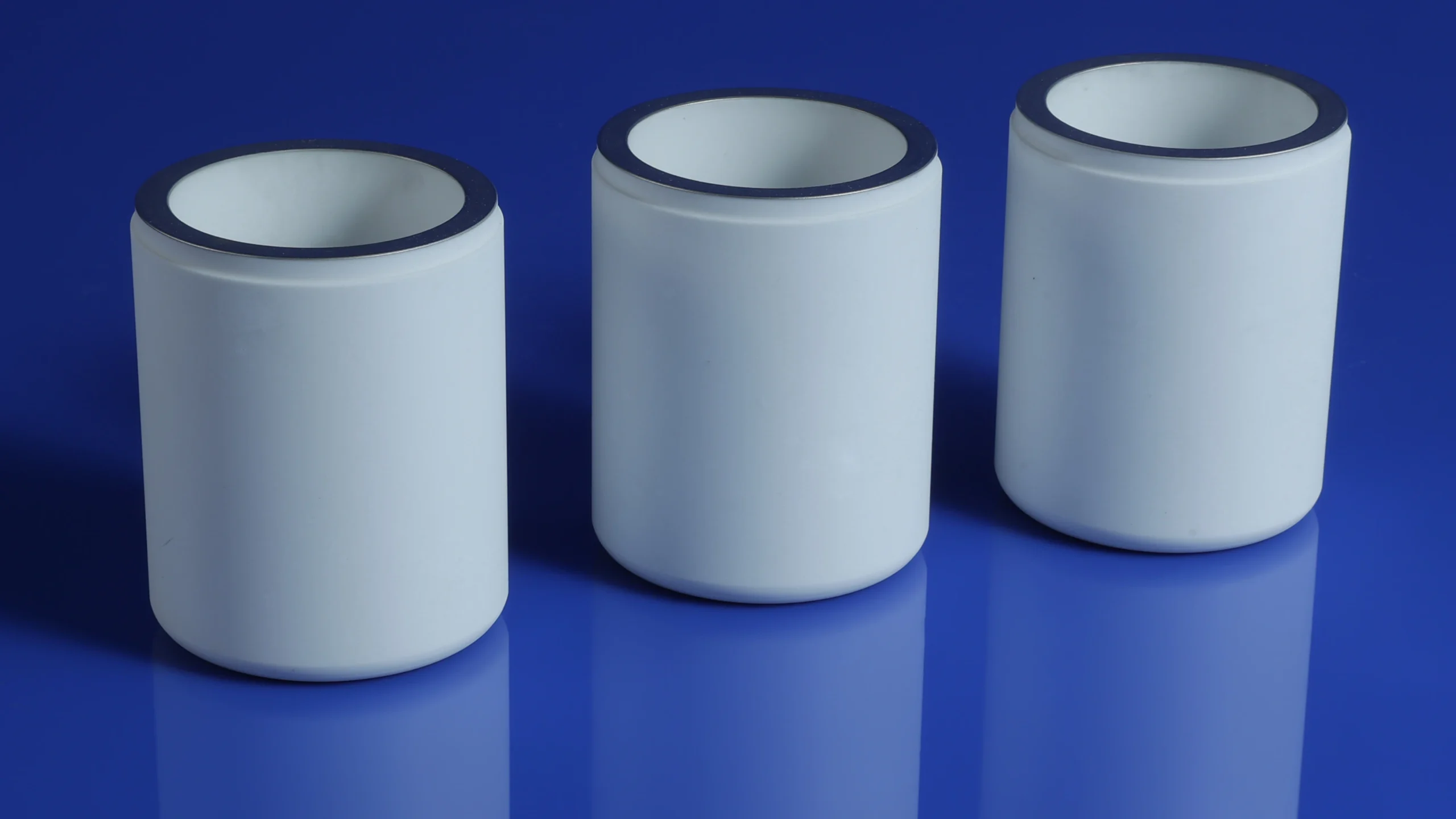

Metallized ceramics are ceramic components that have a thin metallic layer applied to specific surface areas. This layer allows the ceramic to be joined, brazed, or welded to metal components, forming a reliable ceramic-to-metal interface.

Without metallization, joining ceramics to metals would be extremely difficult due to their differences in thermal expansion coefficients5 and lack of chemical affinity. Metallization bridges this gap, ensuring a durable and conductive bond that can withstand extreme operating conditions.

(1)Common Ceramic Substrates:

- Alumina (Al₂O₃) – the most commonly used substrate; provides excellent mechanical strength and insulation.

- Zirconia (ZrO₂) – offers improved fracture toughness and is suitable for high-stress applications.

- Beryllia (BeO) and Aluminum Nitride (AlN) – used for components requiring superior thermal conductivity.

- Silicon Nitride (Si₃N₄) – ideal for applications involving rapid temperature changes and mechanical shocks.

(2)Typical Metallization Materials:

- Molybdenum-Manganese (Mo-Mn)6 – widely used for high-temperature vacuum brazing applications.

- Tungsten (W) – used for high-melting-point or high-strength assemblies.

- Nickel (Ni) – acts as a plating layer to enhance brazing wetting and corrosion resistance.

- Gold (Au) or Silver (Ag) – optional noble metal coatings for enhanced conductivity and oxidation resistance.

2. How the Metallization Process Works

The metallization process involves applying a metal layer to the ceramic surface to create a bondable interface. The Mo-Mn method is the most established process, though direct active brazing is also used in some designs.

(1)The Mo-Mn Process (Classical Method)

- Surface Preparation – The ceramic is cleaned and sometimes roughened using alumina blasting to improve adhesion.

- Paste Application – A paste of molybdenum and manganese powders is applied to the designated bonding area.

- Firing – The coated parts are fired in a hydrogen atmosphere at ~1500°C, causing the Mo-Mn to partially diffuse into the ceramic surface, creating a strong metallurgical bond.

- Nickel Plating – A thin nickel layer (3–10 µm) is electroplated or electrolessly plated over the metallized surface to promote good wetting during brazing and prevent oxidation.

The result is a bondable metal surface on a ceramic body that can be brazed or welded to metals such as Kovar, stainless steel, titanium, or copper alloys.

(2)Alternative Methods

- Direct Active Brazing (DAB): Utilizes brazing alloys with active elements like titanium (Ti) to directly react with ceramic surfaces, eliminating the need for metallization.

- Thick Film and Thin Film Metallization: Screen printing or sputtering metal layers for electronic packaging and microelectronic substrates.

3. Advantages of Metallized Ceramics

Metallized ceramics offer a unique combination of electrical, mechanical, and thermal properties, making them superior to other joining solutions.

| Advantage | Description |

|---|---|

| Hermetic sealing | Gas-tight joints ensure long-term protection in vacuum or pressurized environments. |

| Electrical insulation | Perfect isolation between conductive paths while maintaining structural connections. |

| Thermal stability | Performs reliably from cryogenic to >850°C environments. |

| Mechanical strength | Withstands vibration, stress, and pressure fluctuations. |

| Corrosion resistance | Inert to moisture, chemicals, and oxidation. |

| High reliability | Proven performance in aerospace, defense, and medical certifications. |

Metallized ceramics are also environmentally stable and can operate for decades without degradation.

4. Applications Across Industries

Metallized ceramics are used wherever electrical isolation and hermetic sealing are simultaneously required.

(1)Aerospace & Defense

- Hermetic connectors and feedthroughs

- Pressure sensors and vacuum windows

- High-voltage insulators in propulsion systems

(2)Medical Devices

- Hermetic packages for implantable sensors, pacemakers, and cochlear implants

- High-voltage insulators in diagnostic equipment

- Medical imaging system components

(3)Electronics & Vacuum Technology

- Power tube envelopes and vacuum feedthroughs

- Microwave and X-ray tube housings

- Laser diode packages and photonics assemblies

(4)Energy & Industrial Equipment

- Power transmission insulators

- High-temperature sealing rings

- Ceramic bushings and furnace components

Each of these industries depends on metallized ceramics to ensure signal integrity, safety, and reliability in harsh environments.

5. Metallized Ceramics vs. Other Joining Methods

Compared to adhesives, glass seals, or mechanical joints, metallized ceramics offer unmatched reliability.

| Method | Key Feature | Limitations |

|---|---|---|

| Adhesives | Easy application | Poor thermal resistance, low hermeticity |

| Glass seals | Good electrical insulation | Brittle, prone to cracking under thermal stress |

| Direct brazing | Fast and strong | Less precise control of wetting on ceramics |

| Metallized ceramics | Hermetic, stable, repeatable | Higher initial cost, but superior long-term reliability |

In high-stakes applications, the durability and precision of metallized ceramics far outweigh their production complexity.

6. Quality Control and Testing

Since metallized ceramics are used in mission-critical systems, rigorous testing ensures every part meets performance standards.

Common Tests Include:

- Helium leak testing (per MIL-STD-883, ISO 14644) to verify hermetic integrity.

- Bond strength testing to assess adhesion between the metallized layer and ceramic.

- Thermal cycling (–55°C to 850°C) to ensure long-term reliability.

- Metallographic analysis for layer thickness, uniformity, and interface quality.

- Electrical insulation resistance testing to confirm dielectric performance.

7. Future Trends in Metallized Ceramics

As industries push for higher performance and miniaturization, metallized ceramics continue to evolve:

- Advanced coating techniques such as sputtering and laser-assisted metallization improve precision.

- Hybrid materials combine ceramics with nanocomposites for superior mechanical and thermal behavior.

- Miniaturized vacuum packages enable integration into microelectronic sensors and MEMS devices.

- Green manufacturing reduces waste in metallization and plating processes.

These innovations are expanding metallized ceramics’ role in semiconductors, quantum computing, and high-voltage EV systems.

Conclusion

Metallized ceramics are the backbone of reliable, high-performance assemblies across multiple industries. By merging ceramic insulation with metallic conductivity, they provide solutions that can withstand the harshest environments while ensuring safety, precision, and durability.

If your next project demands hermetic sealing, high dielectric strength, and long service life, metallized ceramics offer a proven path forward.

Looking for customized metallized ceramic components?

Contact our engineering team for consultation, design optimization, and technical datasheets to find the perfect solution for your application.

Explore how strong hermetic seals are crucial for reliability in high-stakes industries. ↩

Learn about thermal cycling and its impact on material performance in extreme conditions. ↩

Understand the process and benefits of creating robust ceramic-to-metal assemblies. ↩

Discover the five remarkable advantages of metallized ceramics in modern electronic devices. ↩

Find out why differences in thermal expansion coefficients matter in material bonding. ↩

Explore the thickness control of Mo-Mn. ↩