10 Types of Hardest Ceramics You NEED for Industrial Applications

As a professional writer specializing in industrial materials and drawing upon a solid understanding of advanced ceramics, I present this authoritative list of the 10 hardest ceramics essential for demanding industrial applications.

| Rank | Ceramic Type | Hardness (HV) | Key Properties & Industrial Applications |

|---|---|---|---|

| 1 | Diamond (Polycrystalline Diamond, PCD) | 8000–10000 | Hardest known material, unmatched wear resistance, high thermal conductivity. Used in cutting tools for non-ferrous metals, wire drawing dies, precision machining. |

| 2 | Cubic Boron Nitride (cBN)1 | ~4500 | Superhard (second only to diamond), thermally stable, chemically inert. Used for machining hardened steels and superalloys, abrasive grinding wheels (alternative to diamond for ferrous materials). |

| 3 | Boron Carbide (B₄C) | ~3000 | Extremely high hardness, lightweight, chemically inert, good neutron absorption. Used in abrasive blasting nozzles, body armor, nuclear applications. |

| 4 | Titanium Diboride (TiB₂) | ~2500–3000 | Exceptional hardness, electrical conductivity, resistance to molten metals. Used in crucibles, cutting tools, electrodes for aluminum smelting. |

| 5 | Silicon Carbide (SiC)2 | ~2800 | Extremely high hardness, excellent thermal conductivity, wear and corrosion resistance. Used in abrasive tools, cutting tools, ballistic armor, high-temperature components (aerospace, automotive). |

| 6 | Tungsten Carbide (WC) | ~2600 | High hardness, toughness (with binder), wear and deformation resistance. Widely used in cutting tools, drill bits, mining equipment, wear-resistant coatings (machining, mining). |

| 7 | Aluminum Oxide (Al₂O₃)3 | ~2000 | High hardness, excellent electrical insulation, corrosion resistance. Used in grinding media, wear-resistant linings, electrical insulators, biomedical implants (cost-effective, versatile). |

| 8 | Silicon Nitride (Si₃N₄) | ~1500–2000 | High strength, thermal shock resistance, low thermal expansion, good wear resistance. Used in bearings, turbine blades, engine components, metalworking tools (high-temperature, high-stress applications). |

| 9 | Chromium Carbide (Cr₃C₂) | ~1300–1800 | High oxidation resistance, wear resistance, thermal stability. Used in wear-resistant coatings, turbine components, high-temperature furnace parts (resistance to wear and oxidation). |

| 10 | Zirconium Dioxide (ZrO₂) | ~1200–1400 | High fracture toughness, thermal stability, wear resistance. Used in pump components, bearings, cutting blades, oxygen sensors (toughness for dynamic systems). |

Drawing further upon my expertise in advanced materials, let's delve deeper into the specific characteristics and industrial significance of each of these remarkably hard ceramics. This analysis provides a more detailed look at why each material earns its place on this essential list.

1. Diamond (Polycrystalline Diamond, PCD)

- Hardness: The absolute pinnacle, 8000–10000 HV. Diamond stands as the hardest naturally occurring and commercially synthesized material.

- Key Properties: Unmatched hardness and wear resistance are its defining features. It also boasts the highest known thermal conductivity. However, it can react with ferrous metals at high temperatures.

- Industrial Applications: Its extreme hardness makes it indispensable for cutting and grinding extremely hard materials, particularly non-ferrous metals, composites, and ceramics. Used extensively in wire drawing dies, precision machining tools, and drilling bits where wear is a primary concern.

- Significance: While expensive, its unparalleled wear life in specific applications justifies the cost, enabling high precision and efficiency in manufacturing processes.

2. Cubic Boron Nitride (cBN)

- Hardness: A close second to diamond, around 4500 HV. This synthetic form of boron nitride is remarkably hard.

- Key Properties: Superhard, excellent thermal stability, and chemically inert, especially resistant to reaction with iron at high temperatures, unlike diamond.

- Industrial Applications: Ideal for machining hardened steels, cast irons, and superalloys, materials where diamond would chemically react or wear rapidly. Used in grinding wheels and cutting tool inserts for automotive and aerospace industries.

- Significance: Fills a crucial gap in machining applications where diamond is unsuitable dueating to chemical reactivity with ferrous materials, offering high performance in high-temperature cutting operations.

3. Boron Carbide (B₄C)

- Hardness: Very high, approximately 3000 HV, making it the third hardest material known after diamond and cBN.

- Key Properties: Extreme hardness, relatively low density, high melting point, and excellent neutron absorption cross-section. It is also chemically inert.

- Industrial Applications: Its hardness and lightness are critical for ballistic armor (vehicle and body armor). Used extensively in abrasive blasting nozzles, water jet cutters, and lapping/polishing media due to its cost-effectiveness relative to diamond and cBN. Its neutron absorption property makes it valuable in nuclear reactor control rods and shielding.

- Significance: Offers a unique blend of hardness, low density, and nuclear properties, making it vital for defense and energy sectors.

4. Titanium Diboride (TiB₂)

- Hardness: Impressively hard, ranging from 2500–3000 HV.

- Key Properties: Exceptional hardness, good electrical conductivity for a ceramic, high melting point, and outstanding resistance to molten metals, particularly aluminum.

- Industrial Applications: Crucial for handling molten aluminum, used for crucibles, electrodes, and components in aluminum reduction cells. Also used in cutting tools and wear-resistant coatings where hardness and conductivity are needed.

- Significance: Its combination of hardness and resistance to molten metals makes it indispensable in the aluminum industry and other high-temperature metallurgical processes.

5. Silicon Carbide (SiC)

- Hardness: High hardness around 2800 HV.

- Key Properties: Possesses a remarkable combination of extreme hardness, excellent thermal conductivity, high-temperature strength, low thermal expansion, and resistance to wear and corrosion. Also a wide bandgap semiconductor.

- Industrial Applications: Widely used in abrasive tools, cutting tools, high-temperature furnace components, kiln furniture, and heat exchangers due to its thermal properties. Its wear resistance is leveraged in mechanical seals, pump parts, and automotive components. Increasingly important in power electronics due to its semiconductor properties.

- Significance: A versatile workhorse ceramic, balancing high hardness with excellent thermal and chemical stability across numerous demanding industrial sectors.

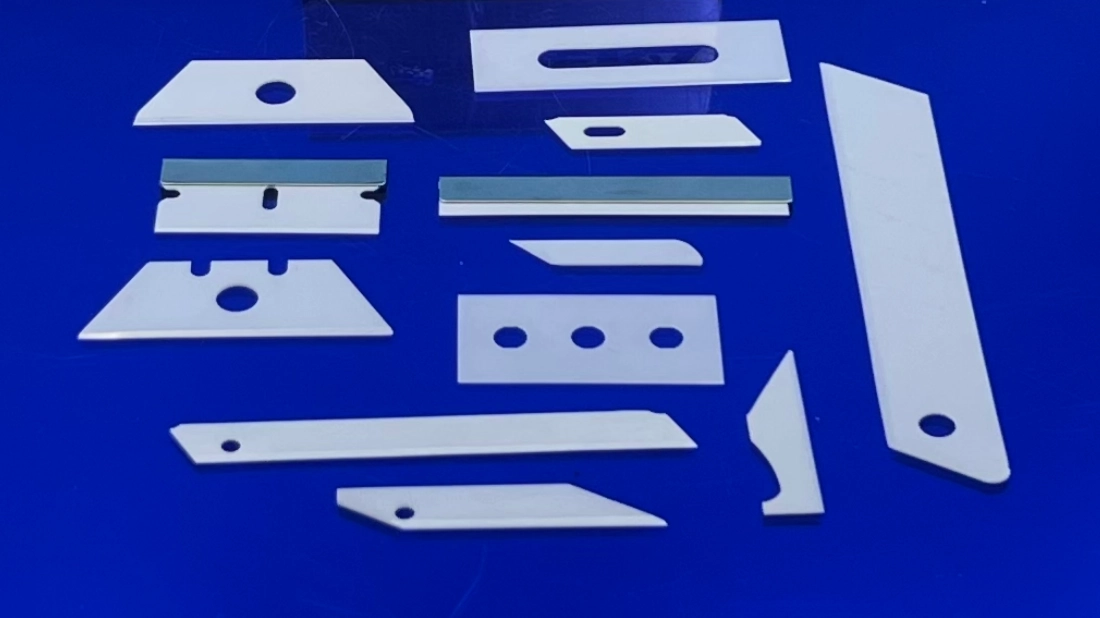

![]()

6. Tungsten Carbide (WC)

- Hardness: High hardness around 2600 HV, typically used with a cobalt binder for improved toughness (forming cemented carbide).

- Key Properties: Exceptional hardness and stiffness, combined with good toughness (depending on binder content and grain size), providing excellent resistance to wear, abrasion, and deformation.

- Industrial Applications: The material of choice for cutting tools (inserts, drill bits, end mills) used in machining metals, wood, and composites. Also critical for mining tools, wear parts (dies, punches), and armor-piercing projectiles.

- Significance: Its unique combination of hardness and toughness makes it the dominant material for many machining and wear applications, handling high mechanical loads effectively.

7. Aluminum Oxide (Al₂O₃), Alumina

- Hardness: Moderately high among hard ceramics, around 2000 HV, varying with purity and processing.

- Key Properties: High hardness, excellent electrical insulation properties, good corrosion resistance, high melting point, and relatively low cost compared to other advanced hard ceramics.

- Industrial Applications: One of the most widely used technical ceramics. Found in grinding media and wheels (as an abrasive), wear-resistant linings, catalyst supports, electrical insulators (substrates, spark plugs), and components for pumps and valves. High-purity alumina is used in biomedical implants.

- Significance: Its cost-effectiveness, coupled with a strong balance of hardness, electrical insulation, and chemical inertness, makes it foundational for numerous industrial and consumer applications.

8. Silicon Nitride (Si₃N₄)

- Hardness: High hardness, typically 1500–2000 HV.

- Key Properties: Renowned for high strength and fracture toughness at high temperatures, excellent thermal shock resistance, low thermal expansion, and good wear resistance. Chemically stable.

- Industrial Applications: Used in demanding high-temperature and high-stress applications such as automotive engine components (glow plugs, turbocharger rotors), high-temperature bearings, turbine blades, and tools for metalworking (welding, extrusion dies). Also used in molten metal handling.

- Significance: Its ability to maintain strength and resist thermal shock at elevated temperatures sets it apart for critical structural components in harsh thermal and mechanical environments.

9. Chromium Carbide (Cr₃C₂)

- Hardness: Hardness ranging from 1300–1800 HV.

- Key Properties: Excellent high-temperature oxidation and corrosion resistance, good wear resistance.

- Industrial Applications: Primarily used as a wear-resistant coating4, often applied via thermal spraying, for components exposed to high temperatures and corrosive atmospheres, such as gas turbine parts, furnace components, and chemical processing equipment. Also used in some cutting tool compositions.

- Significance: Its exceptional resistance to high-temperature oxidation5 distinguishes it for protective coatings in severe environments where other carbides might degrade.

10. Zirconium Dioxide (ZrO₂), Zirconia

- Hardness: Moderate hardness compared to the top list entries, typically 1200–1400 HV.

- Key Properties: While not the hardest, its defining feature is high fracture toughness (especially when stabilized, e.g., Y-TZP), which significantly reduces its brittleness compared to other ceramics. It also has good wear and corrosion resistance, and thermal insulation properties.

- Industrial Applications: Its toughness makes it suitable for components subjected to impact or thermal shock, such as ceramic knives, pump components, bearings, and cutting blades. Used in oxygen sensors, thermal barrier coatings (aerospace), and widely in dental and medical implants due to its biocompatibility and toughness.

- Significance: Provides a critical balance of hardness and toughness, overcoming the inherent brittleness of many other very hard ceramics, enabling applications requiring reliability under stress.

Selecting the optimal ceramic involves balancing hardness with other properties like fracture toughness6, cost, and resistance to specific environmental factors (temperature, chemistry, mechanical stress). Understanding these nuances is key to leveraging the full potential of advanced ceramics in industrial settings.

Explore the unique properties and applications of cBN, a superhard material essential for machining and grinding in various industries. ↩

Learn about SiC's versatility and advantages in high-temperature and abrasive environments, making it a key material in modern manufacturing. ↩

Discover the wide-ranging uses of Al₂O₃, from abrasives to biomedical implants, highlighting its cost-effectiveness and performance. ↩

Discover how wear-resistant coatings improve the longevity and performance of components in harsh environments by exploring this resource. ↩

Exploring this resource will deepen your understanding of how high-temperature oxidation resistance enhances material performance in extreme conditions. ↩

This link will provide insights into the significance of fracture toughness in ceramics, crucial for applications requiring durability and reliability. ↩